See our main article about how to make a motorized skylight shade We also have motorized electric skylight openers.

See our main article about how to make a motorized skylight shade We also have motorized electric skylight openers.

In the main article we showed how to make a remote control 72" x 86" horizontal motorized skylight shade using our RollerTrol™ 12v DC tubular motors and inexpensive off-the-shelf items that can be purchased at your local hardware store. We bought our shade for 39 bucks at our local Home Depot.

This design can also be used to make a bottom up window shade; it would simply be raised into the vertical position.

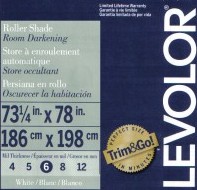

Note the '6' that is highlighted at the bottom of the Levelor label (above, right) - this indicates the weight of the material (Mil thickness), about halfway on the scale of 4 to 12. You can use a different weight, or change the material to suit your needs. You can use double sided tape with a few wraps on it to fasten new material to the roller (such as 3M™ VHB™ RP Tape).

Sequence showing motorized skylight shade at various stages of closing, with multi channel remote (control up to 14 blinds):

Question: Does the weight of the material in your skylight shade cause it to sag? How is it under tension if it isn't rolling up and down? There is nothing on the other side to stretch it, right?

Answer: There is a high tension spring inside the Levelor dispensing roller tube. This is the very common type of shade that is spring loaded, with a locking mechanism that allows you to set it at any height. When you pull it down slightly to release the pawls, it retracts fully to the top of the window.

What we did is remove the locking mechanism so that it is still spring loaded, but doesn't lock any more. So, when the motor pulls it out, the material is kept under tension and you can increase that tension by pre-loading it with a few turns before you attach it to the motor.

We thought we would have problems with sag, and there was some. It's probably ok for small shades. In the video when you see it pulling the blind out horizontally, that frame holds the vinyl material only 1/2" or so off the floor, yet it does not touch. But we did find that the spring weakens over time, causing more sag as it gets older.

This is why we developed the ShadeSlider™ system for cellular shades. It does not rely on spring tension, applying an equal push/pull force on both sides of the shade; you can see the ShadeSlider™ skylight shade motor kit here.

Question: Can your motors be used to make a motorized skylight open and close to let the air in and out? Could the tubular motors be used to open and close ordinary windows?

Answer: The short answer is 'yes'. Our motors can be used in any number of ways, limited only by your imagination. You would probably use chain drive of some kind to do this, but it might be as simple as a pulley used with a roller, or some threaded rod used as a jackscrew, allowing gravity to play its part.

If you come up with an innovative design, let us know and we'll publish it on our website.

The mechanism of this motorized skylight system is remarkably simple: you have a spring loaded shade (locking mechanism removed) at one end of the skylight, a motorized remote control roller at the other end, and some type of pull cord connecting the motorized roller on each side to the roller shade. That is really all you need.

The mechanism of this motorized skylight system is remarkably simple: you have a spring loaded shade (locking mechanism removed) at one end of the skylight, a motorized remote control roller at the other end, and some type of pull cord connecting the motorized roller on each side to the roller shade. That is really all you need.

Here are the instructions for our standard radio motors:

How To Program our Motorized Skylight Shade Kit

We sincerely hope you enjoy using these advanced motors; if you have any questions, please feel free to contact us at any time!

Shopping Cart Home - Start Here

Shopping Cart Home - Start Here Remote Controls for Radio Equipped Motors

Remote Controls for Radio Equipped Motors DIY Starter Kits for Window Shades

DIY Starter Kits for Window Shades DIY Starter Kits for Window Openers

DIY Starter Kits for Window Openers ZWAVE Blind & Shade Controllers

ZWAVE Blind & Shade Controllers How To Choose the Right Blind & Shade Motor

How To Choose the Right Blind & Shade Motor Select tubular Motor (Comparison table)

Select tubular Motor (Comparison table) Choose RollerTrol Battery & Solar Motors

Choose RollerTrol Battery & Solar Motors DIY Roller Blind Motors - FAQ

DIY Roller Blind Motors - FAQ How To Insert Blind Motors & Attach Brackets

How To Insert Blind Motors & Attach Brackets Calculate your Blind or Shade fabric Weight

Calculate your Blind or Shade fabric Weight Select Tube Size for Blind Motor

Select Tube Size for Blind Motor How to Insert Blind Motors Into Tube

How to Insert Blind Motors Into Tube How to Insert Blind Motors Into Tube with Adapters

How to Insert Blind Motors Into Tube with Adapters Attach Mounting Brackets - Standard + Mini Series

Attach Mounting Brackets - Standard + Mini Series Attach Mounting Brackets - MAXI Blind Series

Attach Mounting Brackets - MAXI Blind Series How To Set Up Radio Equipped Blind & Shade Motors

How To Set Up Radio Equipped Blind & Shade Motors Series P Radio Remote Control Motors

Series P Radio Remote Control Motors Series G Radio Remote Control Motors

Series G Radio Remote Control Motors Series R Radio Remote Control Motors

Series R Radio Remote Control Motors BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors How To Set Up Window/Skylight Openers

How To Set Up Window/Skylight Openers Introduction: Window & Skylight (K Series)

Introduction: Window & Skylight (K Series) BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Z-Wave Interfacing for Shade & Opener Motors

Z-Wave Interfacing for Shade & Opener Motors Wired Wall Switch Control of Window Openers

Wired Wall Switch Control of Window Openers How To Use Alexa With Our Motors & Window Openers

How To Use Alexa With Our Motors & Window Openers How To Use BroadLink Phone App Hub With Our Motors

How To Use BroadLink Phone App Hub With Our Motors How To Set Up ShadeSlider Skylight or Bottom-Up Blind

How To Set Up ShadeSlider Skylight or Bottom-Up Blind How To Retrofit RV, Boat and Motorhome Blinds

How To Retrofit RV, Boat and Motorhome Blinds How To Set Up Non-Radio Motors

How To Set Up Non-Radio Motors Operation & Travel Limits of Non-Radio Motors

Operation & Travel Limits of Non-Radio Motors Make a Simple DC Motor Reversing Switch

Make a Simple DC Motor Reversing Switch How To Set Up ZWAVE Control

How To Set Up ZWAVE Control ZWAVE Controller for G Series Radio motors

ZWAVE Controller for G Series Radio motors ZWAVE Door/Window Opening Detection

ZWAVE Door/Window Opening Detection ZWAVE Motion Detector with Temperature Sensing

ZWAVE Motion Detector with Temperature Sensing Motorized Window Blinds & Shades

Motorized Window Blinds & Shades Motorized Dual Window Shade

Motorized Dual Window Shade Make Motorized Blackout Blinds

Make Motorized Blackout Blinds Phone-Tablet-PC Control for Motorized Blinds

Phone-Tablet-PC Control for Motorized Blinds Mini Motor for Existing Shade Retrofit

Mini Motor for Existing Shade Retrofit Roman Shade Retrofit

Roman Shade Retrofit Make a Motorized Window Opener

Make a Motorized Window Opener Blind & Shade Motors for RV & Boats

Blind & Shade Motors for RV & Boats Make Your Own Projector Screen

Make Your Own Projector Screen Curtain Closer: Ultimate Home Theater

Curtain Closer: Ultimate Home Theater Wireless Battery Operated Drapery Motor Kit

Wireless Battery Operated Drapery Motor Kit Make a Motorized Bottom-Up Shade

Make a Motorized Bottom-Up Shade Make a Motorized Skylight Opener

Make a Motorized Skylight Opener BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Why Buy From US?

Why Buy From US? Background & Mission Statement

Background & Mission Statement Customer DIY Testimonials

Customer DIY Testimonials Site Map - Search All Pages

Site Map - Search All Pages Why Buy From US?

Why Buy From US? RollerTrol Users Forum

RollerTrol Users Forum Contact Page

Contact Page