FAQ: Do you have an extra heavy duty 12v motor for large blinds and shades?

Our standard motors are designed to fit Rollease 1.5" tubing, but larger blinds and shades sometimes require a larger size, such as 2.5".

Our Maxi series uses 2.5" tubing (63mm OD) and can lift very large shades and blinds. In this article, we'll show you the various components; these heavy duty motors are really not significantly different from our standard series (including the same radio protocol), except that everything is larger, and the lift capacity is much higher.

This is a very quiet motor, and despite the tremendous lift capacity, it only uses 1.5 A of current @ 12v DC (very efficient too).

Special Note re Extra Large Shades: We often get questions regarding very wide shades for special applications, such as very large projection screens. It can be difficult finding a tube long enough, and the shipping costs can be astronomical.

If you have a metal supplier nearby, this may be the best solution. Yesterday we paid a visit to our local supplier (Metal Supermarket) and it turns out they stock 20 ft lengths of 2 1/2" steel tubing, a near perfect size for our Maxi motors!

If you are doing a retrofit, you would remove the clutch mechanism from one end, where you are going to insert the motor.

Note that the motors can be permanently programmed (with the remote) to operate normally in either direction, so you can choose whichever end you prefer (see blind and shade motor programming instructions).

Further to the retrofit situation, you may also be able to use the existing idler mounting at the other end of the tube, or you may prefer to use the one supplied with the motor, as discussed below.Overview of the parts:

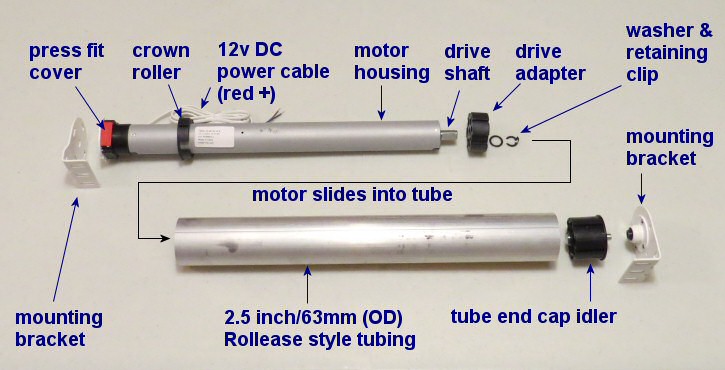

The roller shade motor uses a drive adapter on the end of the drive shaft to rotate the tube, and the rubber crown roller also rotates with the tube. The cylindrical motor housing of the tubular motor remains stationary and is locked to the mounting bracket with tabs.

In the picture above, the crown adapter has been partially slid onto the motor, but not right to the end (left side) where it fits into one end of the tube. You must slide this part on, before you attach the drive adapter to the drive shaft with the provided washer and C clip (there is a retention channel machined into the drive shaft that accepts the clip using finger pressure).

At the other end of the tube, a tube end cap idler is inserted into the tube, and it has an axle that fits into the mounting bracket; the idler rotates freely with the tube. The minimum tube length is 22" (56 cm), slightly longer for the battery series. The actual length of the wired power radio motor version (non battery type) is 20.5" (52 cm) from the outside surface of the motor end to the outside surface of the tube adapter, mounted on the drive shaft.

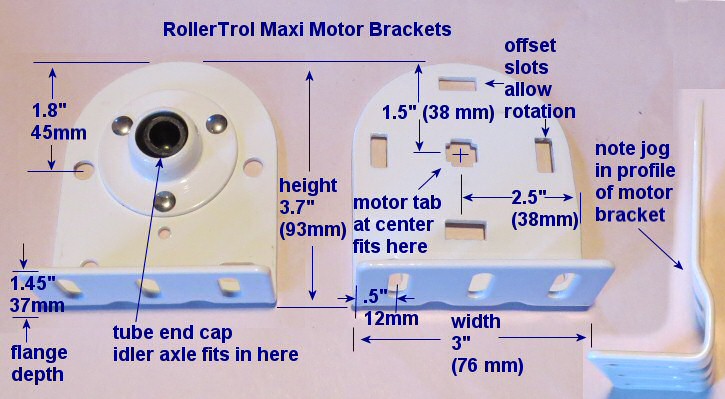

The brackets require 1" of clearance at either end of the tube for mounting purposes. If you have an inside window frame width of 120", the longest tube width (and the largest shade width) you can fit into that frame is 118".

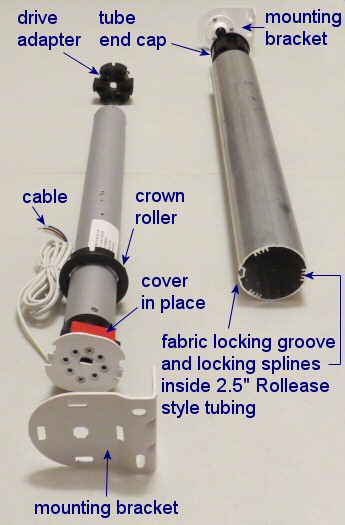

Details of Roller Shade Tubing Structure and Locking Splines:

The pair of pictures below show a closer view of each end. In the left picture, you can clearly see the extruded locking splines that bind the drive adapter (and drive shaft) to the tube so that it can rotate the tube. You can also see the fabric locking slot, but we also use an adhesive strip for fastening the fabric (not shown).

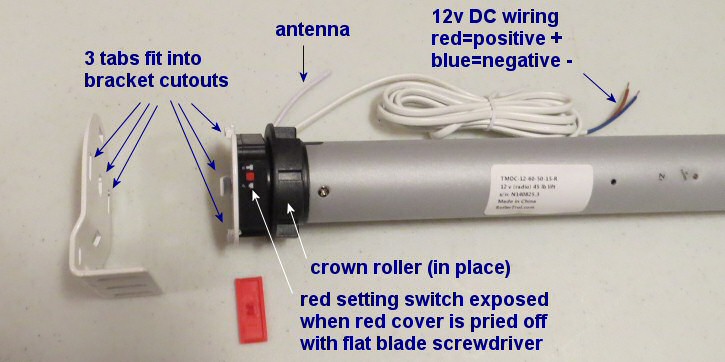

Revealing the Setting Switch, Bracket Attachment Details:

As per the blind and shade motor programming instructions, the setting switch is used to clear the channel assignment memory and to assign a new remote control channel. Note that the bracket for the motor end has a slight jog in the profile; we mention this just in case you are dealing with very tight tolerances in your application.

Maxi Mounting Bracket Dimension Details:

These blind and shade motors can be purchased in the extra heavy duty Maxi section of our online store.

We sincerely hope you enjoy using these advanced motors; if you have any questions, please feel free to contact us at any time!

Shopping Cart Home - Start Here

Shopping Cart Home - Start Here Remote Controls for Radio Equipped Motors

Remote Controls for Radio Equipped Motors DIY Starter Kits for Window Shades

DIY Starter Kits for Window Shades DIY Starter Kits for Window Openers

DIY Starter Kits for Window Openers ZWAVE Blind & Shade Controllers

ZWAVE Blind & Shade Controllers How To Choose the Right Blind & Shade Motor

How To Choose the Right Blind & Shade Motor Select tubular Motor (Comparison table)

Select tubular Motor (Comparison table) Choose RollerTrol Battery & Solar Motors

Choose RollerTrol Battery & Solar Motors DIY Roller Blind Motors - FAQ

DIY Roller Blind Motors - FAQ How To Insert Blind Motors & Attach Brackets

How To Insert Blind Motors & Attach Brackets Calculate your Blind or Shade fabric Weight

Calculate your Blind or Shade fabric Weight Select Tube Size for Blind Motor

Select Tube Size for Blind Motor How to Insert Blind Motors Into Tube

How to Insert Blind Motors Into Tube How to Insert Blind Motors Into Tube with Adapters

How to Insert Blind Motors Into Tube with Adapters Attach Mounting Brackets - Standard + Mini Series

Attach Mounting Brackets - Standard + Mini Series Attach Mounting Brackets - MAXI Blind Series

Attach Mounting Brackets - MAXI Blind Series How To Set Up Radio Equipped Blind & Shade Motors

How To Set Up Radio Equipped Blind & Shade Motors Series P Radio Remote Control Motors

Series P Radio Remote Control Motors Series G Radio Remote Control Motors

Series G Radio Remote Control Motors Series R Radio Remote Control Motors

Series R Radio Remote Control Motors BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors How To Set Up Window/Skylight Openers

How To Set Up Window/Skylight Openers Introduction: Window & Skylight (K Series)

Introduction: Window & Skylight (K Series) BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Z-Wave Interfacing for Shade & Opener Motors

Z-Wave Interfacing for Shade & Opener Motors Wired Wall Switch Control of Window Openers

Wired Wall Switch Control of Window Openers How To Use Alexa With Our Motors & Window Openers

How To Use Alexa With Our Motors & Window Openers How To Use BroadLink Phone App Hub With Our Motors

How To Use BroadLink Phone App Hub With Our Motors How To Set Up ShadeSlider Skylight or Bottom-Up Blind

How To Set Up ShadeSlider Skylight or Bottom-Up Blind How To Retrofit RV, Boat and Motorhome Blinds

How To Retrofit RV, Boat and Motorhome Blinds How To Set Up Non-Radio Motors

How To Set Up Non-Radio Motors Operation & Travel Limits of Non-Radio Motors

Operation & Travel Limits of Non-Radio Motors Make a Simple DC Motor Reversing Switch

Make a Simple DC Motor Reversing Switch How To Set Up ZWAVE Control

How To Set Up ZWAVE Control ZWAVE Controller for G Series Radio motors

ZWAVE Controller for G Series Radio motors ZWAVE Door/Window Opening Detection

ZWAVE Door/Window Opening Detection ZWAVE Motion Detector with Temperature Sensing

ZWAVE Motion Detector with Temperature Sensing Motorized Window Blinds & Shades

Motorized Window Blinds & Shades Motorized Dual Window Shade

Motorized Dual Window Shade Make Motorized Blackout Blinds

Make Motorized Blackout Blinds Phone-Tablet-PC Control for Motorized Blinds

Phone-Tablet-PC Control for Motorized Blinds Mini Motor for Existing Shade Retrofit

Mini Motor for Existing Shade Retrofit Roman Shade Retrofit

Roman Shade Retrofit Make a Motorized Window Opener

Make a Motorized Window Opener Blind & Shade Motors for RV & Boats

Blind & Shade Motors for RV & Boats Make Your Own Projector Screen

Make Your Own Projector Screen Curtain Closer: Ultimate Home Theater

Curtain Closer: Ultimate Home Theater Wireless Battery Operated Drapery Motor Kit

Wireless Battery Operated Drapery Motor Kit Make a Motorized Bottom-Up Shade

Make a Motorized Bottom-Up Shade Make a Motorized Skylight Opener

Make a Motorized Skylight Opener BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Why Buy From US?

Why Buy From US? Background & Mission Statement

Background & Mission Statement Customer DIY Testimonials

Customer DIY Testimonials Site Map - Search All Pages

Site Map - Search All Pages Why Buy From US?

Why Buy From US? RollerTrol Users Forum

RollerTrol Users Forum Contact Page

Contact Page