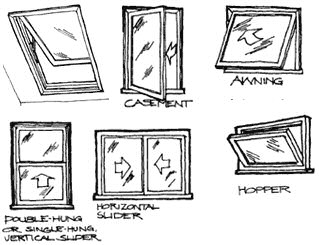

We have safe, remote controlled low voltage electric openers for many different types of windows: awning, hopper, clerestory, single hung vertical sliders, double hung sliders, horizontal sliders, etc. (see how we automate these at the bottom of this page). We also have battery backup capabilities; please see item 7 below.

We are a factory-direct outlet, specializing in home and office automation of 12v window & skylight openers. We also manufacture 12v blind and shade motors, with facilities in New York and Chicago (we ship anywhere in the USA).

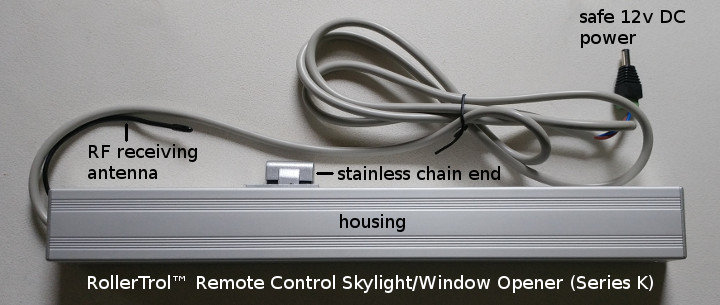

These are RF remote controlled skylight and window openers that you can install yourself.

These are RF remote controlled skylight and window openers that you can install yourself.

They use a stainless steel retractable chain that disappears entirely into a non-obtrusive housing.

These units use safe 12v DC power supplies (or battery operation) that has no shock hazard.

Note that it is particularily important to measure the required lifting force if you are going to use these actuators to lift heavier skylights. We only recommend using the 20 lb actuator for very small skylights; most of our clients use our heavy duty (60+ lb force) opener for skylights.

You can measure the force required to lift a skylight by standing on a bathroom scale and using a long pole to push up on the skylight. You may have to temporarily disconnect any manual lifting mechanism.

How to Order

There are 3 RF remote control models, and these are also available as Starter Kits with power supply and remote control (shopping cart CATEGORY link opens in new browser tab):

1. Standard Remote Control Window Opener (20 lb lift, adjustable stroke)

This unit has an adjustable stroke: 4" (100mm), 8" (200mm), 10" (250mm), 12" (300mm). The stroke can be adjusted by rotating a setting knob on one end of the housing. This unit is suitable for awning windows, vents, hopper windows and small skylights (pictured above).

Shopping cart link for this item (opens in new browser tab}

2. Heavy Duty (HD) Skylight Opener (60+ lb lift, 12" fixed stroke)

This unit has a fixed stroke of 12 inches, but note that it can be stopped at any point of travel by using the RF remote control (which can penetrate solid walls). If you prefer, these units can be custom ordered from the factory with any shortened length of chain stroke.

This unit is suitable for heavy skylights or very large windows that have a lot of frame flex (pictured above, but slightly larger).

Shopping cart link for this item (opens in new browser tab}

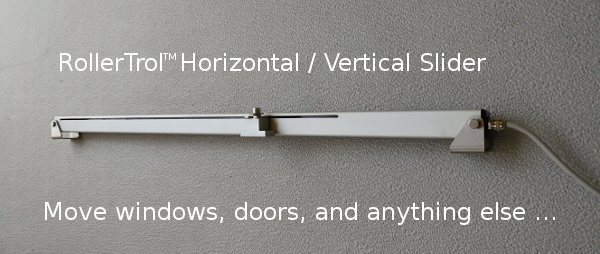

3. Heavy Duty (HD) Vertical Slider Opener (40+ lb lift, custom stroke)

These units are suitable for vertical and horizontal slider windows.

These units are suitable for vertical and horizontal slider windows.

We also have mirrored openers that can go on either side of a particularily stiff vertical slider window.

Please note that these are custom orders only.

Please contact us 24/7 for details

Non-Radio Identical Versions

There are also 3 identical non-radio models that are available. For example, you may have 2 skylights in the same room that you want to open simultaneously.

In this case, you would purchase 1 remote control starter kit and 1 extra non-radio opener (connected in parallel).

Here are the 2 cart links that you would use: cart link for HD Skylight Kit, cart link for extra non-remote HD Skylight Opener.

Alternatively, if you want each skylight to have individual remote control, you would purchase 2 remote control starter kits (cart link for HD Skylight Kit). You can assign 2 channels of the 5 channel remote control, keeping the other remote as a spare.

4. NR Standard Window Opener (20 lb lift, adjustable stroke)

This non-radio unit has an adjustable stroke: 4" (100mm), 8" (200mm), 10" (250mm), 12" (300mm). The stroke can be adjusted by rotating a setting knob on one end of the housing. This unit is suitable for awning windows, vents, hopper windows and small skylights (pictured at top of page).

cart link for extra non-remote Window Opener

5. NR Heavy Duty (HD) Skylight Opener (60+ lb lift, 12" fixed stroke)

This non-radio unit has a fixed stroke of 12 inches, but note that it can be stopped at any point of travel by using the RF remote control (which can penetrate solid walls). If you prefer, these units can be custom ordered from the factory with any length of chain stroke.

This unit is suitable for heavy skylights or very large windows that have a lot of frame flex (pictured at top of page).

cart link for extra non-remote HD Skylight Opener

6. NR Heavy Duty (HD) Vertical Slider Opener (40+ lb lift, custom stroke)

These non-radio units are suitable for vertical and horizontal slider windows.

These non-radio units are suitable for vertical and horizontal slider windows.

We also have mirrored openers that can go on either side of a particularily stiff vertical slider window, pictured here (opens in a new tab).

Please note that these are custom orders only.

Please contact us 24/7 for details

7. Backup Battery Wand for Skylight/Window Openers

Our USB rechargeable battery wand makes a great backup battery uninterruptible power supply (UPS), when grid power fails.

Our USB rechargeable battery wand makes a great backup battery uninterruptible power supply (UPS), when grid power fails.

If you can run a 5v DC USB power line to the battery wand (5v power supply is included with wand), you will have a system that will work, even if grid power is down.

For those of you that experience power interruptions in the winter, this can be a very helpful feature. If you use a 5v solar panel, you can make it a totally independant of grid power!

Remote Control and Automation

As discussed, you can use our multi-channel remote controls to control your window and skylight motors.

Please keep in mind you can also use them with our Broadlink hub, which further extends control to your phone, tablet, laptop or any other web enabled device (whether at home or away).

This article from our sister website contains more information about our automation systems (and using Alexa):

Skylight and window motorized automation

(note that we also have Zwave controllers)

PLEASE NOTE:Care should be exercised when these units are installed where adults or children could get fingers caught in a closing window - serious injury could result. Use of insect screens can help eliminate this possibility.

------- separate page for instructions --------

Instructions for RF Remote Control Window and Skylight Openers

These instructions apply to any of the K series remote control skylight/window opener starter kits (or any custom package), which can include the following:

Wireless RF Remote Controls:

-DCGQ-1H-RF (5 ch)

-DCGQ-15H-RF (15 ch)

-DCGQ-1W-RF (1 ch wall)

-DCGQ-2W-RF (2 ch wall)

-DCGQ-5W-RF (5 ch wall)

Window/Skylight Actuator: WT12v-RX remote control window/skylight/vent opener (20 lb actuator)

OR

Window/Skylight Actuator: WT12v-RR-HD remote control window/skylight/vent opener (60+ lb actuator)

Power Supply: 12v AC/DC power supply (110/240v 50/60 Hz)

Please Note: it is always a good idea to set this up on a table first to test the operation

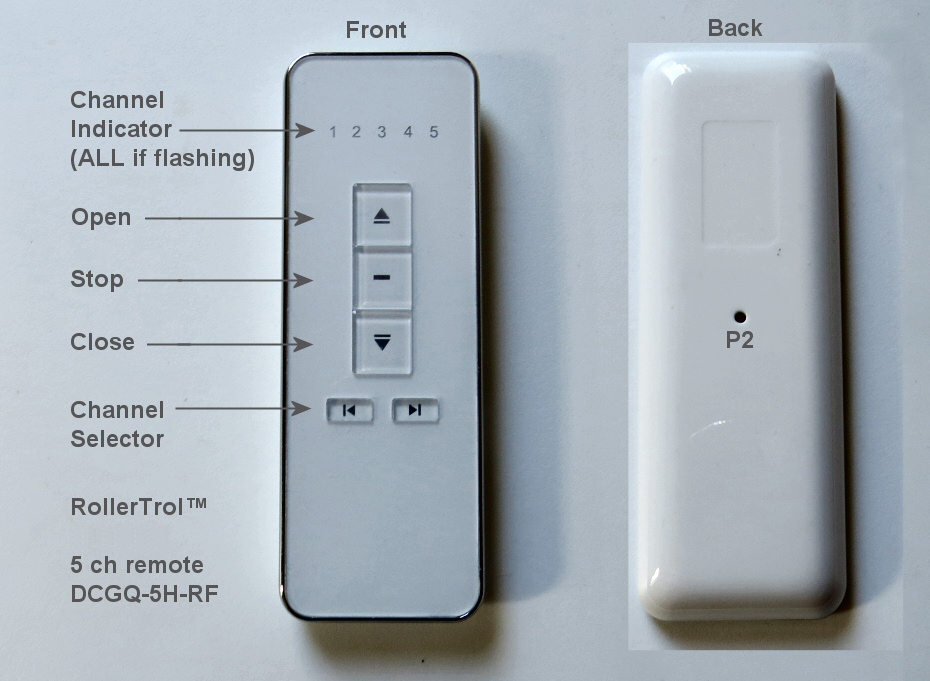

1. The Standard 5 Channel Hand Held Remote:

There is a hole in the back of the remote with a button inside it (the cover does not need to be removed; please familiarize yourself with the location of this switch, it is used to confirm channel assignments and other programming actions. It is referred as P2 in the instructions.

This switch also has tactile feedback, and you do not need to press very hard. Try to use something that is rounded and slightly smaller than the hole as it is possible to miss the switch entirely if you use a pointed object.

There are up / stop / down buttons and channel selector buttons as per the above picture.

You can slide the back cover off the remote control to replace the battery, but these units come with batteries installed and last for years. A slight downward pressure with your thumbs at the top while you slide it off is all that is required.

After removing this cover, you will see the battery compartment at the bottom of the remote. If the button battery is not installed, insert it now. Please pay attention to the battery polarity. The battery has a large plus + sign on one side - this should be facing up, towards you.

Our radio control system is very flexible, here are some notable features:

- Our mult-channel remote controls have up to 15 separate channels + an ALL channel

- Assign individual channel control to each window opener controller AND group them on a different channel

- Assign motors and other 12v devices to different remotes for multiple control points (receivers can hold up to 20 channel assignments)

- The digital control signal is very strong and can usually reach anywhere in a typical home, passing through walls and floors

If you have more than one window opener you can gang the window openers together, connecting them in parallel to create a group that can be controlled simultaneously. The 15 amp receiver can handle up to 6 window openers in a group (or 8 window openers with a light load).

2. Connecting Power to the RollerTrol™ Motor Control Receiver

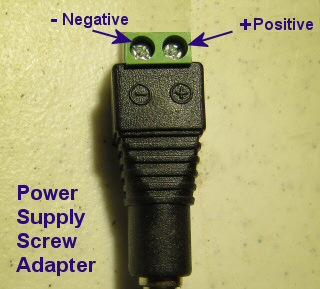

Our 12v power supply that comes with the equipment has a screw adapter on the end to facilitate easy connections.

Our 12v power supply that comes with the equipment has a screw adapter on the end to facilitate easy connections.

It is important to observe polarity (negative and positive screw terminals, as seen in this picture) when connecting the 2 receiver wires to the power supply adapter screw terminals. Brown is positive (+), blue is negative ground (-).

Lamp cord or heavy duty speaker wire works well as wiring for the system, and it is usually available in different colors that can match your decor.

If you want to insert an extender cable so that the power supply is further down the line, that is not a problem. A higher up location can often improve reception.

You will need a small Philips screwdriver to tighten the screw terminals on the adapter. You can use the spring loaded terminal connectors we provide for any other wire connections (provided as a convenience).

3. Connecting the Window Opener to the RollerTrol™ Motor Controller

The 12v actuator (above) is the actual window opening device that will be controlled by the receiver module. It exerts a 20 lb force in any direction and can be used in many different ways, such as horizontal and vertical window sliders, awning windows, skylights - anything that needs to be moved.

The 12v actuator (above) is the actual window opening device that will be controlled by the receiver module. It exerts a 20 lb force in any direction and can be used in many different ways, such as horizontal and vertical window sliders, awning windows, skylights - anything that needs to be moved.

The actuator has a short cable that feeds power to the unit; the wire pair at the end should be connected to the output screw terminals of the RollerTrol™ motor controller module. This can be extended with a single pair wire, if you need to install it further than the supplied cable allows. Lamp cord (#14 or #16) works well, and so does heavy duty speaker wire.

You do not need to observe polarity because reversing these wires simply reverses the action when you press the open/close buttons on the remote control. If you are installing this in a difficult-to-access location, you should know that you can also reverse the motor controller output polarity by directly re-programming it with the remote.

However, we always recommend that you set the system up first on a table so that you can become comfortable with the operation and programming procedures.

4. Installation Tips for the Window/Skylight Opener

Caution: this actuator has more than enough power to injure hands/fingers/paws of children, adults and pets, so please don't use it where it can be reached easily.

Caution: this actuator has more than enough power to injure hands/fingers/paws of children, adults and pets, so please don't use it where it can be reached easily.

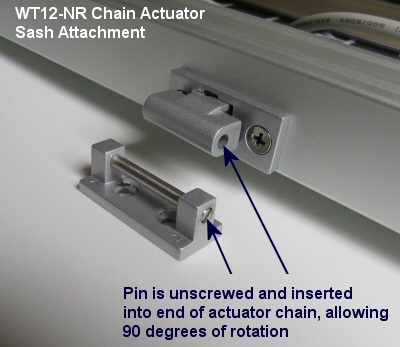

The chain housing is typically mounted on the window sill, and the end of the chain has a special adapter that attaches to the sash frame, allowing for rotation, if required (awning window applications are a good example).

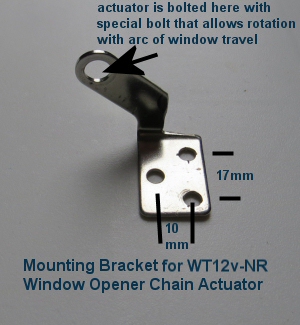

The actuator housing has 3 holes in either end, one of which you will select to suit your particular application (the choice is designed to provide mounting flexibility).

The mounting bracket comes with special bolts that allow it to be fastened securely, yet swivel if the application requires it.

Awning windows are again a good example as the window opener housing has to be able to track the arc of the window sash as it is opened and closed. The chain forms a semi-rigid rod as it emerges from the housing, and simply pushes the window open.

It has a load sensing circuit inside that will detect obstructions that cause it to exceed the 20 lb force, and it will stop automatically if this happens. If you do not want it to open to the full 12" (300 mm) stroke, you can purposely set up an obstruction to make it stop where you want.

Here's a set of pictures kindly provided by one of our customers, showing some details of his installation:

motorized awning window opener installation detail pictures

Here's an example of these actuators used to replace worn out Velux™ skylight motors:

Velux™ skylight motor replacement

Here's an example of horizontal and vertical sliders (single hung) using Pella® fiberglass windows:

motors for window openers: horizontal and vertical sliders (single hung)

5. Preparing the Radio Remote Controls: INTRODUCTION

You may have purchased a multi-channel wall mount remote and/or a hand held remote with your actuator system. The process for assigning the actuator receiver to a channel on your remote is similar for all our remote controls, but there are some slight differences in the location of the P2 setting button on the remotes themselves.

If this is first time use, you will be setting up a master channel on your remote. Once you have established a master channel, you can then easily clone that motor/receiver assignment to any other channel on any other remote (or another channel on the same multi-channel remote remote).

This allows for multiple control locations and motor groupings - it is a very flexible system.

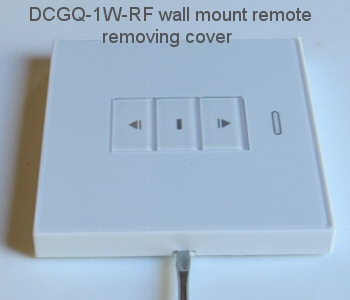

6. Preparing the Wall Mount Radio Remote Control (GQ Series):

These attractive switches are bone white and look good with any decor. The LED indicator flashes when the control buttons are pushed, confirming the OPEN/STOP/CLOSE action. They last for years on a single button battery because there is no current draw in their rest state.

These attractive switches are bone white and look good with any decor. The LED indicator flashes when the control buttons are pushed, confirming the OPEN/STOP/CLOSE action. They last for years on a single button battery because there is no current draw in their rest state.

When you have a number of motors, the usual procedure is to use a multi-channel remote as the MASTER remote that controls the motors on various channels.

This single channel unit can then clone (copy) the digital radio channel signature from the MASTER remote, with a very easy procedure as per the Channel Cloning Procedure below (see the Before You Continue section).

If you only have one remote, you can assign it as the MASTER. In either case, you need to remove the back cover to access the setting switch on the remote.

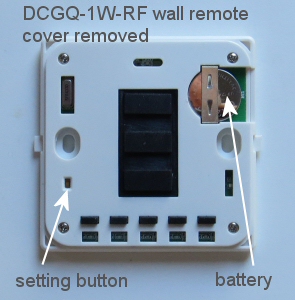

The back cover is removed simply by inserting a small blade screwdriver into the slot on the side of the housing. A gentle rotation of the blade will cause the switch housing to spring apart, exposing the battery compartment and setting switch, as in the picture below.

After removing this cover, you will see the battery compartment at the top right of the remote. If the button battery is not installed, insert it now. Please pay attention to the battery polarity. The battery has a large plus + sign on one side - this should be facing up, towards you.

There is a hole in the opposite lower corner (see picture) of the remote with a button inside it; please familiarize yourself with the location of this button switch, it is used to confirm channel assignments and other programming actions. It is referred as P2 in the instructions.

This switch also has tactile feedback, and you do not need to press very hard. Try to use something that is rounded and slightly smaller than the hole as it is possible to miss the switch entirely if you use a pointed object.

Please Note: If you have a multi-channel version of this remote, the only difference is that you will need to select the channel (using the channel selector button) before you start the cloning or master channel assignment procedures below.

7. Programming ... Before You Continue ...

If you have set up your RollerTrol™ window opener controller on some other remote control 'master', you can very simply clone the window opener controller assignment to this remote (or a different one). You only need to assign a MASTER channel once (starting at Part 6), so if you have already done that, you can just clone the master channel using the following procedure.

RollerTrol™ Channel Cloning Procedure:

- Set the MASTER REMOTE to the master channel you want to clone (if multi-channel type).

- Press and release the P2 button TWICE on the MASTER REMOTE that holds the master channel you want to clone, the window opener controller will beep once each time.

- Press the P2 setting button on the single channel unit, as per the above picture. The window opener will beep 5 times.

- At this point, you are finished - the cloned channel will control the window opener receiver, and you can test it with the window opener or whatever 12v device you have connected.

- Please Note: Wait 10 seconds for programming cycle to complete before you clone another channel.

Note: The following procedures require 6 seconds of pause after completion. Please wait before you try a new procedure.

8. Setting Up The RollerTrol™ MASTER CHANNEL:

AS PER THE PRECEDING NOTE, PLEASE SKIP THIS STEP IF YOU HAVE ALREADY ASSIGNED A MASTER CHANNEL TO THIS WINDOW OPENER CONTROLLER WITH ANOTHER CHANNEL or ANOTHER REMOTE THAT YOU WANT TO KEEP, this procedure erases any previous settings.

Please Note: You have to initiate the programming sequence start within 6 seconds of powering up the receiver, otherwise the operation will time out and you will have to start over. Also, some wall mount remotes use a combination keypress instead of the P2 button, please see wall mount remote control instructions.

- Set the REMOTE to the master channel you want to assign to the window opener (if multi-channel type).

- Apply 12v DC power to the receiver (be sure to observe polarity).

- Press P2 button on the REMOTE, the receiver will beep (wait for it).

- Press P2 button on the REMOTE again, the receiver will beep again.

- Press the UP or DOWN button on the REMOTE CONTROL (this sets travel direction), the radio receiver will beep 6 times; the memory clearing procedure and MASTER assignment is complete.

The operation is done at this point - the memory of the receiver has been cleared, and the master channel has been assigned. You can re-set the memory as many times as you like, but please understand that any other channel assignments will be erased from the receiver. You can add other channels and remotes to this RollerTrol™ window opener controller by following the cloning procedure in the Before You Continue section above.

Note: All procedures require 6 seconds of pause after completion. Please wait before you try a new procedure, or repeat this one.

9. Testing the Window Opener Direction:

You should be able to run a connected window opener at this point - try the UP/DOWN/STOP buttons on the REMOTE. If the window opener runs in the opposite direction to the one desired, you can permanently reverse the window opener direction by reversing the window opener connection wires.

We sincerely hope you enjoy using these advanced systems; if you have any questions, please feel free to contact us at any time!

Shopping Cart Home - Start Here

Shopping Cart Home - Start Here Remote Controls for Radio Equipped Motors

Remote Controls for Radio Equipped Motors DIY Starter Kits for Window Shades

DIY Starter Kits for Window Shades DIY Starter Kits for Window Openers

DIY Starter Kits for Window Openers ZWAVE Blind & Shade Controllers

ZWAVE Blind & Shade Controllers How To Choose the Right Blind & Shade Motor

How To Choose the Right Blind & Shade Motor Select tubular Motor (Comparison table)

Select tubular Motor (Comparison table) Choose RollerTrol Battery & Solar Motors

Choose RollerTrol Battery & Solar Motors DIY Roller Blind Motors - FAQ

DIY Roller Blind Motors - FAQ How To Insert Blind Motors & Attach Brackets

How To Insert Blind Motors & Attach Brackets Calculate your Blind or Shade fabric Weight

Calculate your Blind or Shade fabric Weight Select Tube Size for Blind Motor

Select Tube Size for Blind Motor How to Insert Blind Motors Into Tube

How to Insert Blind Motors Into Tube How to Insert Blind Motors Into Tube with Adapters

How to Insert Blind Motors Into Tube with Adapters Attach Mounting Brackets - Standard + Mini Series

Attach Mounting Brackets - Standard + Mini Series Attach Mounting Brackets - MAXI Blind Series

Attach Mounting Brackets - MAXI Blind Series How To Set Up Radio Equipped Blind & Shade Motors

How To Set Up Radio Equipped Blind & Shade Motors Series P Radio Remote Control Motors

Series P Radio Remote Control Motors Series G Radio Remote Control Motors

Series G Radio Remote Control Motors Series R Radio Remote Control Motors

Series R Radio Remote Control Motors BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors How To Set Up Window/Skylight Openers

How To Set Up Window/Skylight Openers Introduction: Window & Skylight (K Series)

Introduction: Window & Skylight (K Series) BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Z-Wave Interfacing for Shade & Opener Motors

Z-Wave Interfacing for Shade & Opener Motors Wired Wall Switch Control of Window Openers

Wired Wall Switch Control of Window Openers How To Use Alexa With Our Motors & Window Openers

How To Use Alexa With Our Motors & Window Openers How To Use BroadLink Phone App Hub With Our Motors

How To Use BroadLink Phone App Hub With Our Motors How To Set Up ShadeSlider Skylight or Bottom-Up Blind

How To Set Up ShadeSlider Skylight or Bottom-Up Blind How To Retrofit RV, Boat and Motorhome Blinds

How To Retrofit RV, Boat and Motorhome Blinds How To Set Up Non-Radio Motors

How To Set Up Non-Radio Motors Operation & Travel Limits of Non-Radio Motors

Operation & Travel Limits of Non-Radio Motors Make a Simple DC Motor Reversing Switch

Make a Simple DC Motor Reversing Switch How To Set Up ZWAVE Control

How To Set Up ZWAVE Control ZWAVE Controller for G Series Radio motors

ZWAVE Controller for G Series Radio motors ZWAVE Door/Window Opening Detection

ZWAVE Door/Window Opening Detection ZWAVE Motion Detector with Temperature Sensing

ZWAVE Motion Detector with Temperature Sensing Motorized Window Blinds & Shades

Motorized Window Blinds & Shades Motorized Dual Window Shade

Motorized Dual Window Shade Make Motorized Blackout Blinds

Make Motorized Blackout Blinds Phone-Tablet-PC Control for Motorized Blinds

Phone-Tablet-PC Control for Motorized Blinds Mini Motor for Existing Shade Retrofit

Mini Motor for Existing Shade Retrofit Roman Shade Retrofit

Roman Shade Retrofit Make a Motorized Window Opener

Make a Motorized Window Opener Blind & Shade Motors for RV & Boats

Blind & Shade Motors for RV & Boats Make Your Own Projector Screen

Make Your Own Projector Screen Curtain Closer: Ultimate Home Theater

Curtain Closer: Ultimate Home Theater Wireless Battery Operated Drapery Motor Kit

Wireless Battery Operated Drapery Motor Kit Make a Motorized Bottom-Up Shade

Make a Motorized Bottom-Up Shade Make a Motorized Skylight Opener

Make a Motorized Skylight Opener BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Why Buy From US?

Why Buy From US? Background & Mission Statement

Background & Mission Statement Customer DIY Testimonials

Customer DIY Testimonials Site Map - Search All Pages

Site Map - Search All Pages Why Buy From US?

Why Buy From US? RollerTrol Users Forum

RollerTrol Users Forum Contact Page

Contact Page