In part 1 we discussed how the MCS-1-RF wireless window mounted light sensor can be used to activate our radio equipped blind and shade motors using RF (Radio Frequency). In part 2, we will become familiar with the layout of the controls and features of the unit.

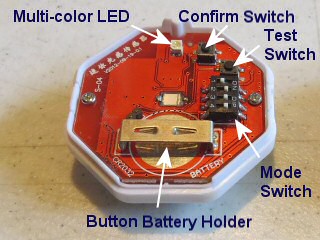

At this point the light sensor cover should be removed, the battery inserted into the battery compartment, and the light sensor unit powered up, as shown in the picture on the right.

Also, please note that the 'confirm' switch behaves the same way as the switch of the same name on our regular remote controls (re channel assignment). You will, however, need a regular remote control to set travel limits on the blind motor.

An important point that makes this system unique: the motor operation can be reversed. This means that if you are attempting to block bright sunlight, you can close the blinds when the light gets bright, and open them if it becomes cloudy. If you are using it to close the blinds at dusk and open them at dawn, just reverse the motor operation. You can also use this sensor with a timer to facilitate light sensitive operation for blind & shade control AND timed operation.

The following is a brief description of the switches, lights and adjustments used to program the unit for unattended operation, starting at the top with the LED light and moving clockwise around the circuit board. Please refer to part 4 for a detailed description of each item:

1. Multi-color LED:

This red/green LED is used to indicate various states during the setup phase, and motor activity during normal operation.

2. Confirm Switch:

The confirm switch is used to pair the motor with the sensor unit. When pressed, it causes the unit to issue a 'handshake' signal while the motor is put into a special 'listening' mode (see part 3). The motor decodes the handshake signal and stores it in its onboard memory system. Once the code is stored, the motor will recognize any subsequent commands coming from the sensor unit when the daylight thresholds are reached.

3. Up/Down/Stop Test Switch:

This switch is used to configure and test various settings during the setup phase. During normal operation it can be toggled to issue up, down and stop commands. The sequence is Roller UP (red LED), Roller STOP (red + green LED), Roller DOWN (green LED), Roller STOP (red + green LED).

4. DIP Mode Switch:

This multi-pole DIP (Dual Inline Package) switch is actually 4 switches in 1. It is used for setting the modes of operation, and there are several different ways this light sensor can be deployed:

- Weak Light Level Operation: The blind is activated only when it gets dark. This is useful if you want to manually open the blinds with a hand held remote in the morning (or open the blind with a timer).

- Strong Light Level Operation: The blind is activated only when it gets bright. This is useful if you want to manually close the blinds with a hand held remote in the evening (or close the blind with a timer).

- Cracked Glass Operation: This light sensor has the ability to detect sudden rapid changes in light level, such as when forced entry is attempted by smashing a window. This can be useful in storefront situations where metal roller security blinds are used in display windows; it is not normally used in domestic applications.

Multi-mode: You can also use any combination of the above 3 modes, including weak and strong light level operation, so that the blinds will close at night and open in the morning as soon as daylight appears.

PART 1: Sunlight sensor for blinds - Removing the Cover

PART 2: Sunlight sensor for blinds - Controls and Layout

PART 3: Sunlight sensor for blinds - Linking to a Radio Motor

PART 4: Sunlight sensor for blinds - Adjusting Light Sensing Modes

We sincerely hope you enjoy using these advanced motors; if you have any questions, please feel free to contact us at any time!

Shopping Cart Home - Start Here

Shopping Cart Home - Start Here Remote Controls for Radio Equipped Motors

Remote Controls for Radio Equipped Motors DIY Starter Kits for Window Shades

DIY Starter Kits for Window Shades DIY Starter Kits for Window Openers

DIY Starter Kits for Window Openers ZWAVE Blind & Shade Controllers

ZWAVE Blind & Shade Controllers How To Choose the Right Blind & Shade Motor

How To Choose the Right Blind & Shade Motor Select tubular Motor (Comparison table)

Select tubular Motor (Comparison table) Choose RollerTrol Battery & Solar Motors

Choose RollerTrol Battery & Solar Motors DIY Roller Blind Motors - FAQ

DIY Roller Blind Motors - FAQ How To Insert Blind Motors & Attach Brackets

How To Insert Blind Motors & Attach Brackets Calculate your Blind or Shade fabric Weight

Calculate your Blind or Shade fabric Weight Select Tube Size for Blind Motor

Select Tube Size for Blind Motor How to Insert Blind Motors Into Tube

How to Insert Blind Motors Into Tube How to Insert Blind Motors Into Tube with Adapters

How to Insert Blind Motors Into Tube with Adapters Attach Mounting Brackets - Standard + Mini Series

Attach Mounting Brackets - Standard + Mini Series Attach Mounting Brackets - MAXI Blind Series

Attach Mounting Brackets - MAXI Blind Series How To Set Up Radio Equipped Blind & Shade Motors

How To Set Up Radio Equipped Blind & Shade Motors Series P Radio Remote Control Motors

Series P Radio Remote Control Motors Series G Radio Remote Control Motors

Series G Radio Remote Control Motors Series R Radio Remote Control Motors

Series R Radio Remote Control Motors BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors How To Set Up Window/Skylight Openers

How To Set Up Window/Skylight Openers Introduction: Window & Skylight (K Series)

Introduction: Window & Skylight (K Series) BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Z-Wave Interfacing for Shade & Opener Motors

Z-Wave Interfacing for Shade & Opener Motors Wired Wall Switch Control of Window Openers

Wired Wall Switch Control of Window Openers How To Use Alexa With Our Motors & Window Openers

How To Use Alexa With Our Motors & Window Openers How To Use BroadLink Phone App Hub With Our Motors

How To Use BroadLink Phone App Hub With Our Motors How To Set Up ShadeSlider Skylight or Bottom-Up Blind

How To Set Up ShadeSlider Skylight or Bottom-Up Blind How To Retrofit RV, Boat and Motorhome Blinds

How To Retrofit RV, Boat and Motorhome Blinds How To Set Up Non-Radio Motors

How To Set Up Non-Radio Motors Operation & Travel Limits of Non-Radio Motors

Operation & Travel Limits of Non-Radio Motors Make a Simple DC Motor Reversing Switch

Make a Simple DC Motor Reversing Switch How To Set Up ZWAVE Control

How To Set Up ZWAVE Control ZWAVE Controller for G Series Radio motors

ZWAVE Controller for G Series Radio motors ZWAVE Door/Window Opening Detection

ZWAVE Door/Window Opening Detection ZWAVE Motion Detector with Temperature Sensing

ZWAVE Motion Detector with Temperature Sensing Motorized Window Blinds & Shades

Motorized Window Blinds & Shades Motorized Dual Window Shade

Motorized Dual Window Shade Make Motorized Blackout Blinds

Make Motorized Blackout Blinds Phone-Tablet-PC Control for Motorized Blinds

Phone-Tablet-PC Control for Motorized Blinds Mini Motor for Existing Shade Retrofit

Mini Motor for Existing Shade Retrofit Roman Shade Retrofit

Roman Shade Retrofit Make a Motorized Window Opener

Make a Motorized Window Opener Blind & Shade Motors for RV & Boats

Blind & Shade Motors for RV & Boats Make Your Own Projector Screen

Make Your Own Projector Screen Curtain Closer: Ultimate Home Theater

Curtain Closer: Ultimate Home Theater Wireless Battery Operated Drapery Motor Kit

Wireless Battery Operated Drapery Motor Kit Make a Motorized Bottom-Up Shade

Make a Motorized Bottom-Up Shade Make a Motorized Skylight Opener

Make a Motorized Skylight Opener BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Why Buy From US?

Why Buy From US? Background & Mission Statement

Background & Mission Statement Customer DIY Testimonials

Customer DIY Testimonials Site Map - Search All Pages

Site Map - Search All Pages Why Buy From US?

Why Buy From US? RollerTrol Users Forum

RollerTrol Users Forum Contact Page

Contact Page