These instructions apply to any of the chain type window/skylight openers.

Please Note: it is always a good idea to set this up on a table first to test the operation

1. Introduction

We have various 12v window/skylight chain openers (depending on lift capacity) that can be controlled by RF multi-channel remotes or simple switches.

We have various 12v window/skylight chain openers (depending on lift capacity) that can be controlled by RF multi-channel remotes or simple switches.

They use the same special mounting brackets that allow the housing to track the arc of window and skylight openers.

We always recommend that you set the system up first on a table so that you can become comfortable with the operation and programming procedures.

Caution: this actuator has more than enough power to injure hands/fingers/paws of children, adults and pets, so please don't use it where it can be reached easily, without some kind of barrier to prevent mishaps.

Bug screens are typically used, with a hole cut out for the actuator chain, with horsehair protecting the cut-out from insect intrusion.

2. The Chain Pushes The Window/Skylight Open

For window openers, the chain housing is typically mounted on the window sill.

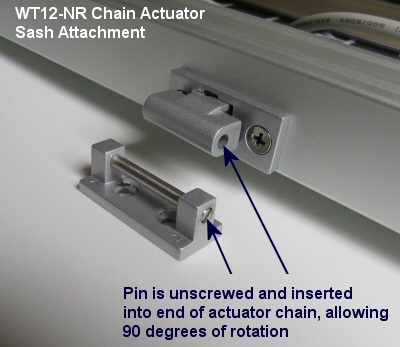

The end of the chain has a special adapter that attaches to the sash frame, allowing for rotation, if required (awning window applications are a good example).

The pin is unscrewed from the sash bracket and inserted in the "nose piece" of the chain, then the sash bracket can be bolted or screwed to the window sash.

For skylight openers, the setup is similar, but typically the actuator is rotated 90 degrees to push (and open) the skylight.

Our 20 lb (9 kg) opener is only rated to lift very small skylights; we normally use our 60+ lb. HD (heavy duty) opener for heavy skylights.

You can test the force required to open a skylight by standing on a bathroom scale and pushing the skylight open with a long pole (you may have to release any mechanism that is used to open the skylight).

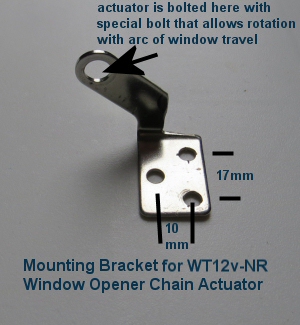

If you look at this picture of the mounting bracket, you'll see the extra large hole that allows the mounting bolts to rotate and track the arc of the window or skylight opening, with with special bolts that allow it to be fastened securely, yet swivel if the application requires it.

If you look at this picture of the mounting bracket, you'll see the extra large hole that allows the mounting bolts to rotate and track the arc of the window or skylight opening, with with special bolts that allow it to be fastened securely, yet swivel if the application requires it.

The actuator housing has 3 holes in either end, one of which you will select to suit your particular application (the choice is designed to provide mounting flexibility).

If you have a very short chain excursion, you may be able to anchor the actuator in a fixed position, but we don't recommend this because the chain can jam part way.

Awning windows are again a good example as the window opener housing has to be able to track the arc of the window sash as it is opened and closed. The chain forms a semi-rigid rod as it emerges from the housing, and simply pushes the window open.

It has a load sensing circuit inside that will detect obstructions that cause it to exceed the 20 lb (9 kg) force, and it will stop automatically if this happens. These actuators have an adjustable stroke: 4" (100mm), 8" (200mm), 10" (250mm), 12" (300mm), and these units work well with motorized awning windows because most of the weight is supported by the hinges.

Here's a set of pictures kindly provided by one of our customers, showing some details of his installation:

motorized awning window opener installation detail pictures

Here's an example of these actuators used to replace worn out Velux™ skylight motors:

Velux™ skylight motor replacement

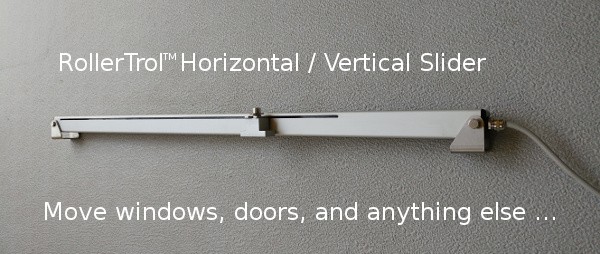

Here's an example of horizontal and vertical sliders (single hung) using Pella® fiberglass windows:

motors for window openers: horizontal and vertical sliders (single hung)

3. Threaded Screw Openers for STICKY Vertical Sliders

We also have special threaded screw actuators for "very sticky" vertical sliders. These can also be "mirrored" so that they can be placed on either side of the vertical slider. These units are rated at 40 lb. lift capacity.

As an alternative, you could use our 60+ lb. chain actuator to push up and open it, if you don't mind the chain in the middle of the window opening.

We sincerely hope you enjoy using these advanced systems; if you have any questions, please feel free to contact us at any time!

Shopping Cart Home - Start Here

Shopping Cart Home - Start Here Remote Controls for Radio Equipped Motors

Remote Controls for Radio Equipped Motors DIY Starter Kits for Window Shades

DIY Starter Kits for Window Shades DIY Starter Kits for Window Openers

DIY Starter Kits for Window Openers ZWAVE Blind & Shade Controllers

ZWAVE Blind & Shade Controllers How To Choose the Right Blind & Shade Motor

How To Choose the Right Blind & Shade Motor Select tubular Motor (Comparison table)

Select tubular Motor (Comparison table) Choose RollerTrol Battery & Solar Motors

Choose RollerTrol Battery & Solar Motors DIY Roller Blind Motors - FAQ

DIY Roller Blind Motors - FAQ How To Insert Blind Motors & Attach Brackets

How To Insert Blind Motors & Attach Brackets Calculate your Blind or Shade fabric Weight

Calculate your Blind or Shade fabric Weight Select Tube Size for Blind Motor

Select Tube Size for Blind Motor How to Insert Blind Motors Into Tube

How to Insert Blind Motors Into Tube How to Insert Blind Motors Into Tube with Adapters

How to Insert Blind Motors Into Tube with Adapters Attach Mounting Brackets - Standard + Mini Series

Attach Mounting Brackets - Standard + Mini Series Attach Mounting Brackets - MAXI Blind Series

Attach Mounting Brackets - MAXI Blind Series How To Set Up Radio Equipped Blind & Shade Motors

How To Set Up Radio Equipped Blind & Shade Motors Series P Radio Remote Control Motors

Series P Radio Remote Control Motors Series G Radio Remote Control Motors

Series G Radio Remote Control Motors Series R Radio Remote Control Motors

Series R Radio Remote Control Motors BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors How To Set Up Window/Skylight Openers

How To Set Up Window/Skylight Openers Introduction: Window & Skylight (K Series)

Introduction: Window & Skylight (K Series) BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Z-Wave Interfacing for Shade & Opener Motors

Z-Wave Interfacing for Shade & Opener Motors Wired Wall Switch Control of Window Openers

Wired Wall Switch Control of Window Openers How To Use Alexa With Our Motors & Window Openers

How To Use Alexa With Our Motors & Window Openers How To Use BroadLink Phone App Hub With Our Motors

How To Use BroadLink Phone App Hub With Our Motors How To Set Up ShadeSlider Skylight or Bottom-Up Blind

How To Set Up ShadeSlider Skylight or Bottom-Up Blind How To Retrofit RV, Boat and Motorhome Blinds

How To Retrofit RV, Boat and Motorhome Blinds How To Set Up Non-Radio Motors

How To Set Up Non-Radio Motors Operation & Travel Limits of Non-Radio Motors

Operation & Travel Limits of Non-Radio Motors Make a Simple DC Motor Reversing Switch

Make a Simple DC Motor Reversing Switch How To Set Up ZWAVE Control

How To Set Up ZWAVE Control ZWAVE Controller for G Series Radio motors

ZWAVE Controller for G Series Radio motors ZWAVE Door/Window Opening Detection

ZWAVE Door/Window Opening Detection ZWAVE Motion Detector with Temperature Sensing

ZWAVE Motion Detector with Temperature Sensing Motorized Window Blinds & Shades

Motorized Window Blinds & Shades Motorized Dual Window Shade

Motorized Dual Window Shade Make Motorized Blackout Blinds

Make Motorized Blackout Blinds Phone-Tablet-PC Control for Motorized Blinds

Phone-Tablet-PC Control for Motorized Blinds Mini Motor for Existing Shade Retrofit

Mini Motor for Existing Shade Retrofit Roman Shade Retrofit

Roman Shade Retrofit Make a Motorized Window Opener

Make a Motorized Window Opener Blind & Shade Motors for RV & Boats

Blind & Shade Motors for RV & Boats Make Your Own Projector Screen

Make Your Own Projector Screen Curtain Closer: Ultimate Home Theater

Curtain Closer: Ultimate Home Theater Wireless Battery Operated Drapery Motor Kit

Wireless Battery Operated Drapery Motor Kit Make a Motorized Bottom-Up Shade

Make a Motorized Bottom-Up Shade Make a Motorized Skylight Opener

Make a Motorized Skylight Opener BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Why Buy From US?

Why Buy From US? Background & Mission Statement

Background & Mission Statement Customer DIY Testimonials

Customer DIY Testimonials Site Map - Search All Pages

Site Map - Search All Pages Why Buy From US?

Why Buy From US? RollerTrol Users Forum

RollerTrol Users Forum Contact Page

Contact Page