These instructions apply to the IVK-12-SW motorized ball valve starter kit, which includes the following:

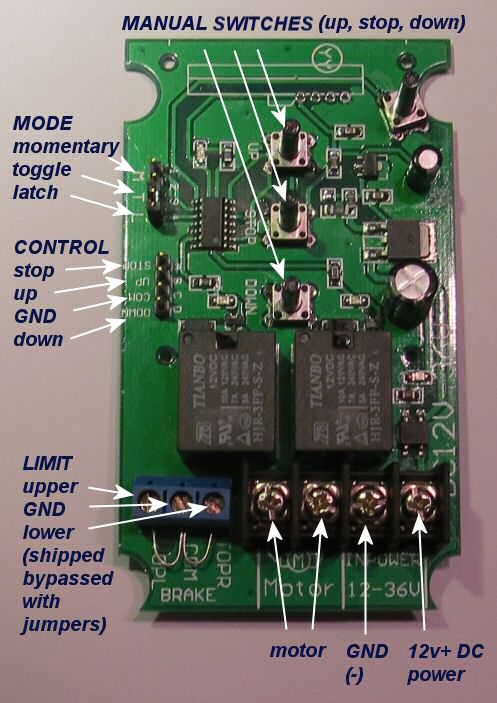

DCC-1W-12-24 wired wall switch motor controller

12v AC/DC power supply (110/240v 50/60 Hz)

Introduction

Our 12v motorized irrigation ball valve is used as an example in these instructions, but this wired wall switch can be used as a control system for any standard 12v DC motor or device. This would include items such as blind and shade motors, fans, LED lighting, etc.

In these instructions, we are using our wired wall switch controller that comes with the kit, which is one of the devices in our NodeSwitch™ Motor Control series. We also have Z-Wave add-on trigger modules and other digital radio remote control systems.

You can also integrate this very easily with any home automation system from companies such as Vera®, Insteon®, Z-Wave®, Wink®, SmartThings®, Zigbee®, Crestron® and Control4®. Any home automation system that has dry contact output (ie relay capability) will work with this switch.

The wiring is very simple:

- Connect the 2 wires of the ball valve to the 2 motor screw terminals of the switch (polarity does not matter, other than it reverses the direction of travel).

- Connect the 2 wires from the power supply to the input power terminals (polarity does matter).

- Plug in the power supply, and the switch will now operate the valve.

1. Open Switch Housing to Locate Power & Motor Screw Terminals

We always recommend that you set the system up first on a table so that you can become comfortable with the operation and programming procedures.

You will need some wire to connect the DC power supply to the controller switch and/or to extend the wire from your valve motor.

Ordinary lamp cord works well, but you may need fire rated cable for in-wall or plenum applications.

There are 4 recessed screws on the back of the switch in each corner that will allow the 2 halves of the switch housing to come apart. You'll need a small Philips screw driver to open the housing.

The interface has 3 modes of jumper controlled operation: latched, momentary, and toggle.

The default setting is latched, and is the most common method of usage; if you change the mode jumper, you'll need to power down the unit first.

The switch can handle up to 10 amps of current (120 watts @ 12v DC), which is enough to power about 15 valves simultaneously, depending on loads (power supply should also be upgraded to provide suitable power output).

You later expand your system to include more valves as we do supply just the valves themselves; we can also provide larger power supplies, if required. Since this system operates on 12v, you can also run it from a small 12v car or motorcycle battery, with a trickle charger and/or solar panel.

2. Connecting Power to the NodeSwitch™ Wired Wall Switch

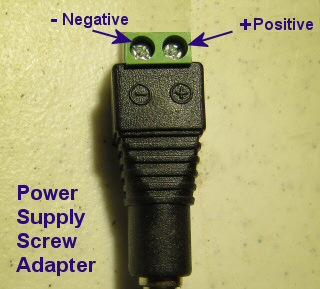

The 12v power supply that comes with the kit has a screw adapter on the end to facilitate easy connections.

The 12v power supply that comes with the kit has a screw adapter on the end to facilitate easy connections.

It is important to observe polarity (negative and positive wires, as seen in this picture) when connecting the 2 power supply wires (not provided) to the radio motor controller power input terminals.

Lamp cord or heavy duty speaker wire works well as wiring for the system, and it is usually available in different colors that can match your decor.

You will need a small Philips screwdriver to tighten the screw terminals on the adapter and controller board.

We recommend that you get a set of small jeweller's screwdrivers for this purpose. We also provide a white 2 pole spring loaded wire connector that you can use however you like.

3. Connecting the Valve to the Switch

The valve has a short cable that feeds power to the unit; the wire pair at the end should be connected to the output screw terminals of the NodeSwitch™ motor controller module. This can be extended with a single pair wire, if you need to install it further than the supplied cable allows. Lamp cord (#14 or #16) works well, and so does heavy duty speaker wire.

You do not need to observe polarity because reversing these wires simply reverses the action when you press the open/close buttons on the switch control.

We sincerely hope you enjoy using these advanced systems; if you have any questions, please feel free to contact us at any time!

Shopping Cart Home - Start Here

Shopping Cart Home - Start Here Remote Controls for Radio Equipped Motors

Remote Controls for Radio Equipped Motors DIY Starter Kits for Window Shades

DIY Starter Kits for Window Shades DIY Starter Kits for Window Openers

DIY Starter Kits for Window Openers ZWAVE Blind & Shade Controllers

ZWAVE Blind & Shade Controllers How To Choose the Right Blind & Shade Motor

How To Choose the Right Blind & Shade Motor Select tubular Motor (Comparison table)

Select tubular Motor (Comparison table) Choose RollerTrol Battery & Solar Motors

Choose RollerTrol Battery & Solar Motors DIY Roller Blind Motors - FAQ

DIY Roller Blind Motors - FAQ How To Insert Blind Motors & Attach Brackets

How To Insert Blind Motors & Attach Brackets Calculate your Blind or Shade fabric Weight

Calculate your Blind or Shade fabric Weight Select Tube Size for Blind Motor

Select Tube Size for Blind Motor How to Insert Blind Motors Into Tube

How to Insert Blind Motors Into Tube How to Insert Blind Motors Into Tube with Adapters

How to Insert Blind Motors Into Tube with Adapters Attach Mounting Brackets - Standard + Mini Series

Attach Mounting Brackets - Standard + Mini Series Attach Mounting Brackets - MAXI Blind Series

Attach Mounting Brackets - MAXI Blind Series How To Set Up Radio Equipped Blind & Shade Motors

How To Set Up Radio Equipped Blind & Shade Motors Series P Radio Remote Control Motors

Series P Radio Remote Control Motors Series G Radio Remote Control Motors

Series G Radio Remote Control Motors Series R Radio Remote Control Motors

Series R Radio Remote Control Motors BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors How To Set Up Window/Skylight Openers

How To Set Up Window/Skylight Openers Introduction: Window & Skylight (K Series)

Introduction: Window & Skylight (K Series) BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Z-Wave Interfacing for Shade & Opener Motors

Z-Wave Interfacing for Shade & Opener Motors Wired Wall Switch Control of Window Openers

Wired Wall Switch Control of Window Openers How To Use Alexa With Our Motors & Window Openers

How To Use Alexa With Our Motors & Window Openers How To Use BroadLink Phone App Hub With Our Motors

How To Use BroadLink Phone App Hub With Our Motors How To Set Up ShadeSlider Skylight or Bottom-Up Blind

How To Set Up ShadeSlider Skylight or Bottom-Up Blind How To Retrofit RV, Boat and Motorhome Blinds

How To Retrofit RV, Boat and Motorhome Blinds How To Set Up Non-Radio Motors

How To Set Up Non-Radio Motors Operation & Travel Limits of Non-Radio Motors

Operation & Travel Limits of Non-Radio Motors Make a Simple DC Motor Reversing Switch

Make a Simple DC Motor Reversing Switch How To Set Up ZWAVE Control

How To Set Up ZWAVE Control ZWAVE Controller for G Series Radio motors

ZWAVE Controller for G Series Radio motors ZWAVE Door/Window Opening Detection

ZWAVE Door/Window Opening Detection ZWAVE Motion Detector with Temperature Sensing

ZWAVE Motion Detector with Temperature Sensing Motorized Window Blinds & Shades

Motorized Window Blinds & Shades Motorized Dual Window Shade

Motorized Dual Window Shade Make Motorized Blackout Blinds

Make Motorized Blackout Blinds Phone-Tablet-PC Control for Motorized Blinds

Phone-Tablet-PC Control for Motorized Blinds Mini Motor for Existing Shade Retrofit

Mini Motor for Existing Shade Retrofit Roman Shade Retrofit

Roman Shade Retrofit Make a Motorized Window Opener

Make a Motorized Window Opener Blind & Shade Motors for RV & Boats

Blind & Shade Motors for RV & Boats Make Your Own Projector Screen

Make Your Own Projector Screen Curtain Closer: Ultimate Home Theater

Curtain Closer: Ultimate Home Theater Wireless Battery Operated Drapery Motor Kit

Wireless Battery Operated Drapery Motor Kit Make a Motorized Bottom-Up Shade

Make a Motorized Bottom-Up Shade Make a Motorized Skylight Opener

Make a Motorized Skylight Opener BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Why Buy From US?

Why Buy From US? Background & Mission Statement

Background & Mission Statement Customer DIY Testimonials

Customer DIY Testimonials Site Map - Search All Pages

Site Map - Search All Pages Why Buy From US?

Why Buy From US? RollerTrol Users Forum

RollerTrol Users Forum Contact Page

Contact Page