Introduction to Thermostatic Control of Window Motors

Adrian Biffen, Senior Partner

Controlling the temperature in a greenhouse is critical for healthy plant growth. The ideal temperature range depends on the types of plants being grown, the season, and other environmental factors. Using thermostatic control allows growers to automatically control the temperature and create the optimal climate for their crops.

This article will provide an overview of how a thermostat can be used to control greenhouse temperatures. These are key considerations when selecting and installing a thermostat, including tips for maximizing vent and heating efficiency.

Please note that all our thermostats, window motors, and motorized louvers (with remote control) operate on 12 volts DC and therefore have no shock hazard. If you want to control thermostats, you just simply plug in our electric window openers and louvers. Our power supplies plug into a standard wall outlet plug.

The picture below shows the front of the thermostat that has various setpoints:

What is a Greenhouse Thermostat?

Thermostatic controls are devices that monitor and regulate temperature in a greenhouse. It contains a thermometer to measure the current temperature and adjusts heating or cooling systems to maintain the target temperature span set by the user.

Thermostatic control typically contains the following components:

- Temperature sensor probe - Measures the current air temperature fluctuations using a thermocouple, thermistor, or resistance temperature detector (RTD). This input is used to activate heating or cooling if the temperature deviates from the setpoint.

- Control panel - Allows the user to program the desired temperature bounds and setpoints. May include a digital screen to display current temperature.

- Switching mechanism - Turns the heating thermostat or cooling thermostat on or off based on the current temperature and setpoint. This is usually a relay or solid-state switch.

- Heating/cooling outputs - Our thermostatic control has 2 dry contact relays that control heaters, heat mats and cooling. You can also connect to ventilation fans, air conditioners, or other climate control equipment.

Many thermostats come with additional features like window opener control, humidity measurement, light level monitoring, louver activation, and alarms. These provide growers with expanded environmental regulation for optimal plant growth.

Benefits of Using a Temperature Controller Digital Thermostat

Maintaining the ideal temperature is crucial for plant health and productivity. Thermostatic control offers several key benefits:

- Precision temperature controller - This type of thermostat is very accurate with temperature regulation - within +/- 1°F. This prevents extreme temperature swings that stress plants.

- Energy efficiency - Precise temperature settings control prevents over-heating or over-cooling, saving energy.

- Reliability - Electronics regulate temperature consistently for long periods without drift. No manual adjustment needed.

- Flexibility - These units can control various devices like heat mats, louvres, evaporative coolers, and more.

By maintaining consistent temperatures and preventing fluctuations, these temperature monitors optimize the growing environment and can lead to increased plant quality, growth rates, and yields.

Key Considerations for Digital Thermostat Selection

When choosing thermostatic control, key factors to consider include:

- Does your choice of thermostatic control involve 120 volts AC? If so, please consider our greenhouse kits that are 12v units with no shock hazard.

- Temperature range - Match the thermostatic control capabilities with the ideal temperature span for the crops being grown. Most plants grow best with day temperatures of 65-75°F and night temperatures of 55-65°F.

- Accuracy and precision - Look for thermostatic control that regulate within +/- 1°F of setpoint to prevent swings. Models with a digital display offer higher accuracy.

- Durability - Select a thermostatic controller built for the greenhouse environment that monitors high temperature and humidity, condensation, dirt, etc. Waterproof temperature models are best.

- Heating/cooling capacity - Match the thermostatic control to the capacity of the heating/cooling equipment it will activate. This is measured in amps.

- Power source - Thermostatic control can be powered by DC power, AC power, batteries, or a combination.

- Alarm capabilities - Models with temperature alarms that notify growers of heating/cooling failures or extremes can prevent crop damage.

- Budget - thermostatic control ranges from $50 to $500. Balance cost against durability, accuracy, and features.

Proper Installation of Thermostatic Control for Accuracy and Reliability

To achieve the highest accuracy and reliability from thermostatic control, proper installation is key:

- Mounting location - Install on an interior wall around 5 feet high. Choose a location away from drafts and heat sources for accurate temperature measurement.

- Wiring - Use the appropriate wire gauge for thermostatic control. Separate power and control wiring for best performance. Follow all electrical codes.

- Temperature sensing - Place the remote probe in the plant canopy to read leaf temperature. Shield it from direct sun or thermal radiation.

- Heating/cooling equipment - Properly size and install HVAC equipment based on the greenhouse dimensions and thermostatic capacity. Follow all codes.

- Programming - Set temperature differential wide enough to prevent short cycling of equipment (e.g. 2°F). Configure setback temperatures and desired day/night ranges.

- Testing and calibration - Run through heating/cooling cycles to confirm proper wiring. Calibrate the thermostatic control if temperature readings are off.

Taking the time to correctly install the thermostatic controller will maximize its accuracy and ability to maintain optimal growing temperatures.

How to Use a Thermostat for Temperature Control of Heat Mats, Exhaust Fans, Etc

Programming and using a thermostatic controller provides growers with precise greenhouse climate control. Key steps for temperature regulation include:

- Set the current date/time on the thermostatic controller so auto-changing setpoints function properly.

- Program the desired daytime temperature span based on the crop - for example, 70-80°F for warm-weather plants.

- Enter night time setback temperatures that are 5-10°F cooler to save energy.

- Configure the controller differential to avoid excess cycling (e.g. +/- 2°F).

- Set vents to temperature maximums ~10° higher to control fans.

- Connect controller terminals to control temperature equipment like portable heaters, heat mats, or HVAC units.

- Monitor the measured temperature on the thermostatic display to spot inconsistencies.

- Use alarms and minimum/maximum temperature alerts to catch significant climate deviations quickly.

- Adjust setpoints seasonally as outside temperatures change.

- Perform annual maintenance like calibration, battery changes, and testing of connected equipment.

Following the manufacturer's instructions to program setpoints, configure equipment, and set alarms will allow growers to leverage the full capabilities of a thermostatic controller. Monitoring and tweaking the system based on plant needs optimizes the temperature.

Typical Heating and Cooling Mode Equipment for Greenhouses

Thermostatic control works by adjusting various types of heating and cooling systems to maintain the desired temperature bounds. Typical equipment used includes:

- Electric or hydronic heaters - Provide greenhouse heating mode using electric heating elements or hot water/steam hydronic systems. Thermostats directly control electric units or valves on hydronic systems.

- Forced air furnaces - Fuel-fired forced air furnaces heat air which is circulated by greenhouse fans and ductwork. Thermostats regulate the fan and heat.

- Infrared heaters - Emit targeted infrared radiation to heat plants and surfaces. The controller directly modulates infrared output.

- Heat retention systems - Passive heating systems like thermal curtains and insulation are controlled by thermostats cutting power at setpoints.

- Evaporative coolers - Cool air through evaporative cooling. Thermostats activate pumps and control fans to activate cooling levels.

- Exhaust fans - Remove hot air to lower temperatures. Thermostatic control powers variable speed fans to regulate cooling.

- Air conditioners - Provide active cooling like wall-mounted AC units. Thermostatic control directly switches the AC on and off.

- Circulation fans - Improve air mixing and temperature consistency. Controlled by thermostatic dry contact relays.

The variety of temperature technologies that interface with thermostatic control provides extensive climate control options.

Optimizing Temperature Management Efficiency

Greenhouse operators can leverage temperature controller thermostats to maximize temperature efficiency in several ways:

- Implement setback temperatures - Program 10-15°F lower temperatures at night to conserve energy since sunlight heating is not present.

- Zone heating/cooling - Separate the greenhouse into isolated temperature zones controlled by multiple controllers only operating when zones are occupied.

- Variable speed equipment - Use thermostats to control devices, such as variable output heaters, fans, misting systems, and AC units only at the level needed, saving energy.

- Passive solar gain - Orient greenhouse glazing to maximize winter solar gain for free daytime heating. Thermostatic control regulates temperature to prevent overheating.

- Insulation - Add insulating materials to walls to improve heat retention. This allows the thermostatic control to maintain warmth with less active heating.

- Weather automation - Have thermostats adjust heating/cooling based on changing outdoor weather like cloud cover or temperature.

- Maintenance - Regularly calibrate thermostats, clean temperature probe, check wiring, and test connected equipment to ensure optimal performance.

Leveraging setpoints, equipment staging, and passive heating/cooling strategies allows growers to minimize energy usage while maintaining ideal temperatures.

Care of Seedlings

Young seedlings are delicate and require careful attention to grow into healthy, productive plants. The greenhouse environment allows close control over critical factors for development. Follow these tips to give the best start:

Lighting - They need 14-16 hours of bright light daily. Supplement natural light with grow lights placed close to the plants. Fluorescent tubes or LED panels work well.

Temperature - Maintain temperatures around 70°F during the day and 60-65°F at night. Use a thermostatic controller to regulate greenhouse heaters and vents.

Watering - Check soil moisture daily and water when the top inch is dry. Use a gentle spray nozzle to avoid dislodging seeds. Don't let plants wilt or soil get soggy.

Fertilizer - Begin fertilizing once the first true leaves emerge. Use a diluted, balanced fertilizer once a week.

Spacing - Transplant plants when the first true leaves appear. Space them 2-3 inches apart to allow air circulation and growth.

Humidity - They grow well at 60-70% relative humidity. Use fans for air circulation and misters/humidifiers to raise humidity.

Pests/Diseases - Inspect for pests like fungus gnats or diseases daily. Isolate and remove any affected plants promptly. Control problems before they spread.

Hardening Off - Gradually expose them to outdoor conditions over 1-2 weeks before transplanting to avoid shock. Harden off by setting plants outside for short periods.

Frequently Asked Questions About Temperature Regulators

Q: What temperature span do most plants grow best in?

A: Most greenhouse crops grow best with day temperatures of 65-75°F and night temperatures of 55-65°F. Tropical plants prefer 75-85°F days. Specific crop needs vary.

Q: How much does a typical thermostat cost?

A: Basic models start around $50. Most robust thermostats for full climate control run $150 to $300. Advanced computerized systems can cost over $1000.

Q: How often should thermostat setpoints be adjusted?

A: Review setpoints weekly and adjust as needed based on the season, plant growth stage, and weather. Do not change more than 2-3 degrees per day to avoid plant stress.

Q: What sensors can I connect to an environmental control computer to monitor conditions?

A: Typical sensors include air and soil temperature, humidity controllers, light intensity, CO2 level, ventilation status, and equipment on/off status. This data helps optimize control.

Q: My thermostat display does not match a thermometer. How do I perform calibration?

A: Follow manufacturer instructions to enter an offset that matches the display to a calibrated reference thermometer reading at a stable temperature.

Conclusion For Greenhouse Temperature Control

Thermostats provide growers with precision temperatures critical for plant growth and productivity. Selecting the right thermostat and properly installing heating/cooling equipment enables maintenance of optimal climate conditions. Careful programming of setpoints, use of alarms, and efficiency strategies allow maximization of growth while minimizing energy usage. With the right thermostat system, growers can elevate their operation and provide an ideal environment for plants and crops.

Contact Us 24/7

We sincerely hope you enjoyed this article about using these advanced 12v motorized windows, shade blinds, and louvers; if you have any questions, please feel free to contact us at any time!

Shopping Cart Home - Start Here

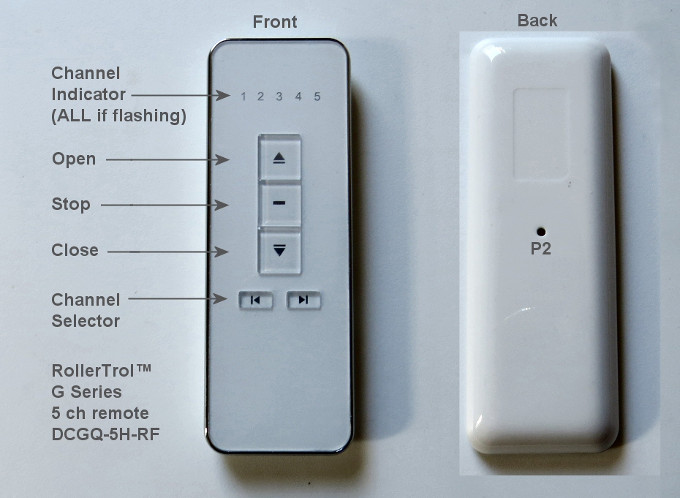

Shopping Cart Home - Start Here Remote Controls for Radio Equipped Motors

Remote Controls for Radio Equipped Motors DIY Starter Kits for Window Shades

DIY Starter Kits for Window Shades DIY Starter Kits for Window Openers

DIY Starter Kits for Window Openers ZWAVE Blind & Shade Controllers

ZWAVE Blind & Shade Controllers How To Choose the Right Blind & Shade Motor

How To Choose the Right Blind & Shade Motor Select tubular Motor (Comparison table)

Select tubular Motor (Comparison table) Choose RollerTrol Battery & Solar Motors

Choose RollerTrol Battery & Solar Motors DIY Roller Blind Motors - FAQ

DIY Roller Blind Motors - FAQ How To Insert Blind Motors & Attach Brackets

How To Insert Blind Motors & Attach Brackets Calculate your Blind or Shade fabric Weight

Calculate your Blind or Shade fabric Weight Select Tube Size for Blind Motor

Select Tube Size for Blind Motor How to Insert Blind Motors Into Tube

How to Insert Blind Motors Into Tube How to Insert Blind Motors Into Tube with Adapters

How to Insert Blind Motors Into Tube with Adapters Attach Mounting Brackets - Standard + Mini Series

Attach Mounting Brackets - Standard + Mini Series Attach Mounting Brackets - MAXI Blind Series

Attach Mounting Brackets - MAXI Blind Series How To Set Up Radio Equipped Blind & Shade Motors

How To Set Up Radio Equipped Blind & Shade Motors Series P Radio Remote Control Motors

Series P Radio Remote Control Motors Series G Radio Remote Control Motors

Series G Radio Remote Control Motors Series R Radio Remote Control Motors

Series R Radio Remote Control Motors BroadLink RF/IR Hub System for Motors

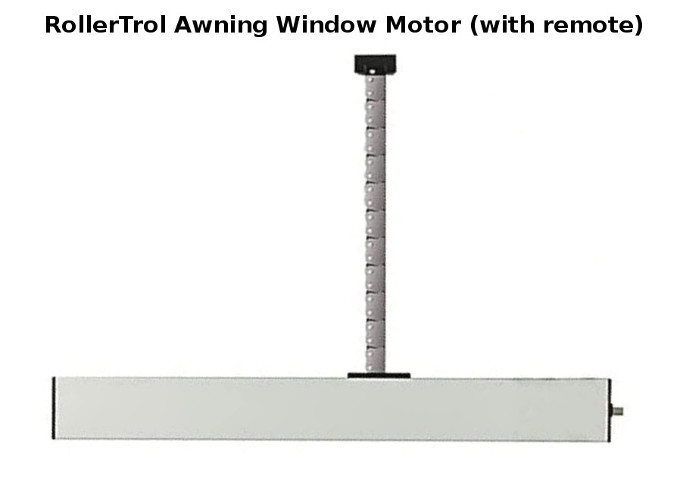

BroadLink RF/IR Hub System for Motors How To Set Up Window/Skylight Openers

How To Set Up Window/Skylight Openers Introduction: Window & Skylight (K Series)

Introduction: Window & Skylight (K Series) BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Z-Wave Interfacing for Shade & Opener Motors

Z-Wave Interfacing for Shade & Opener Motors Wired Wall Switch Control of Window Openers

Wired Wall Switch Control of Window Openers How To Use Alexa With Our Motors & Window Openers

How To Use Alexa With Our Motors & Window Openers How To Use BroadLink Phone App Hub With Our Motors

How To Use BroadLink Phone App Hub With Our Motors How To Set Up ShadeSlider Skylight or Bottom-Up Blind

How To Set Up ShadeSlider Skylight or Bottom-Up Blind How To Retrofit RV, Boat and Motorhome Blinds

How To Retrofit RV, Boat and Motorhome Blinds How To Set Up Non-Radio Motors

How To Set Up Non-Radio Motors Operation & Travel Limits of Non-Radio Motors

Operation & Travel Limits of Non-Radio Motors Make a Simple DC Motor Reversing Switch

Make a Simple DC Motor Reversing Switch How To Set Up ZWAVE Control

How To Set Up ZWAVE Control ZWAVE Controller for G Series Radio motors

ZWAVE Controller for G Series Radio motors ZWAVE Door/Window Opening Detection

ZWAVE Door/Window Opening Detection ZWAVE Motion Detector with Temperature Sensing

ZWAVE Motion Detector with Temperature Sensing Motorized Window Blinds & Shades

Motorized Window Blinds & Shades Motorized Dual Window Shade

Motorized Dual Window Shade Make Motorized Blackout Blinds

Make Motorized Blackout Blinds Phone-Tablet-PC Control for Motorized Blinds

Phone-Tablet-PC Control for Motorized Blinds Mini Motor for Existing Shade Retrofit

Mini Motor for Existing Shade Retrofit Roman Shade Retrofit

Roman Shade Retrofit Make a Motorized Window Opener

Make a Motorized Window Opener Blind & Shade Motors for RV & Boats

Blind & Shade Motors for RV & Boats Make Your Own Projector Screen

Make Your Own Projector Screen Curtain Closer: Ultimate Home Theater

Curtain Closer: Ultimate Home Theater Wireless Battery Operated Drapery Motor Kit

Wireless Battery Operated Drapery Motor Kit Make a Motorized Bottom-Up Shade

Make a Motorized Bottom-Up Shade Make a Motorized Skylight Opener

Make a Motorized Skylight Opener BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Why Buy From US?

Why Buy From US? Background & Mission Statement

Background & Mission Statement Customer DIY Testimonials

Customer DIY Testimonials Site Map - Search All Pages

Site Map - Search All Pages Why Buy From US?

Why Buy From US? RollerTrol Users Forum

RollerTrol Users Forum Contact Page

Contact Page