3D Printing for Blind and Shade Motor Adapters

We have been active in the 3D CAD industry for over 30 years, with powerful CAD class computers that can handle the task of building 3D virtual models for items associated with blind motors, such as tube adapters. We also have 3D printers that are well suited for printing tube adapters for blinds and shades, using the layer deposition method.

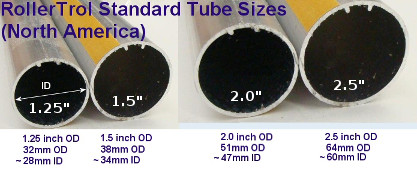

Our stock adapters are made for industry-standard Rollease® tubing, which is the most common aluminum tube size in North America (see TUBE sizes pictured below). It is important to understand that TUBE sizes are measure by OD (Outer Diameter), as opposed to PIPE sizes, measured by ID (Inner Diameter).

At our Custom Shade Division we often manufacture blinds and shades for very large windows that require a wider tube roller. This also means we have to increase the tube diameter to 2" to combat sag (known also as 'smiley face'), and sometimes 2.5" for extreme sizes.

At our Custom Shade Division we often manufacture blinds and shades for very large windows that require a wider tube roller. This also means we have to increase the tube diameter to 2" to combat sag (known also as 'smiley face'), and sometimes 2.5" for extreme sizes.

We also manufacture heavy duty motors that can handle the larger sizes with ease, and we have 'in house' capabilities for producing the required adapters for these larger blinds and shades. This allows us to optimize the design of these adapters so that they fit perfectly, without any slop that can affect motor performance.

Three Adapters Required for Each Motorized Blind or Shade

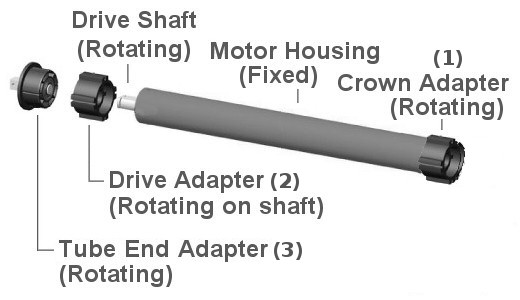

There are 3 adapters that need to have the diameter increased for each blind, regardless of the size we are stepping up to, whether the tube diameter is 2 inch or 2 1/2 inch. This schematic picture shows where the 3 important adapters are located; these are the standard 1.5" adapters, before any step-up adapters are added:

- (1) CROWN ROLLER (positioned at fixed motor head, rotates with tube on lubricated slip ring, providing support for tube end)

- (2) MOTOR DRIVE ADAPTER (positioned inside tube on motor axle, drives tube rotation. This critical drive adapter should be locked to the tube with a setscrew if you are using a tube with a smooth inner wall)

- (3) END CAP IDLER (positioned at opposite end from motor, rotates with tube on axle, providing support for tube end)

Upsizing Drive Adapters for Blind & Shade Motors

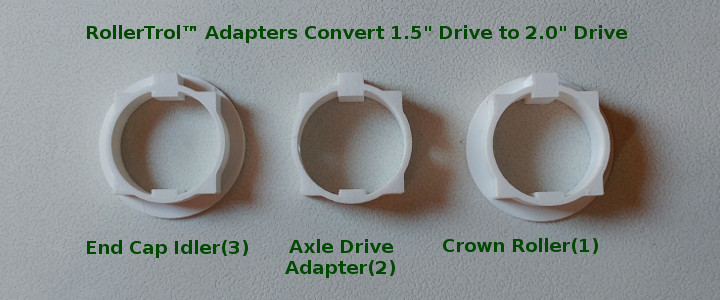

The next sequence of pictures reveal how our manufactured adapters allow a motor to drive a 2.0 inch tube, instead of 1.5 inch. Please note that we have used the same identification protocol as above: crown roller (1), axle drive adapter (2), tube end cap idler (3).

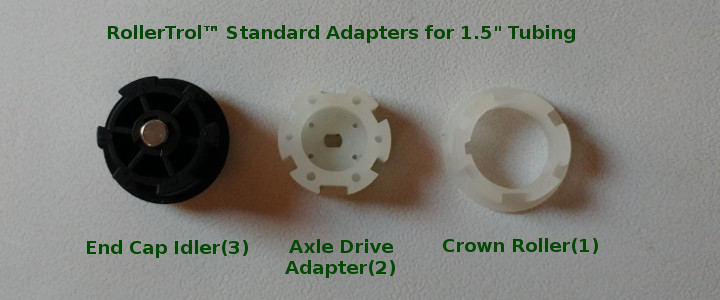

The first picture below shows what the standard 1.5" adapters actually look like (but please note they sometimes come in different colors (eg. black or gray instead of white, and vice-versa):

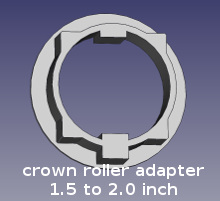

Here are the upsizing adapters we produce with our CAD system and 3D printers:

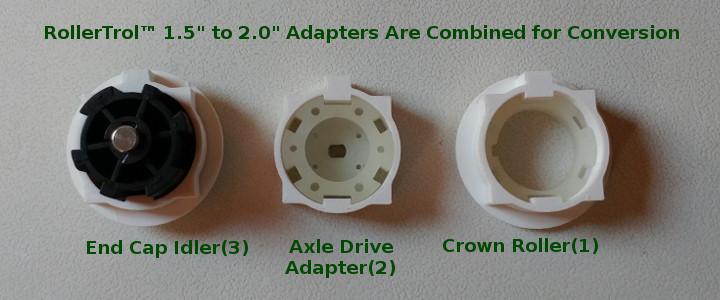

This picture below shows how the new adapters are combined with the original standard adapters to "upsize" and drive a 2" tube. Please note that that the upsizing adapter needs to be attached to the drive adapter so that it cannot slip off (you could use some glue):

Special Attention: Drive Shaft Adapter

The drive shaft adapter (center in above picture) that is driven by the motor axle requires some special attention.

If you are using a tube with a smooth inside wall that might allow the drive system to slip, you can use a setscrew to lock the adapter to the tube. Please keep in mind that there is a steel reinforcing plate embedded inside the 1.5" drive adapter that is faintly visible, so please make sure your screw is short enough to avoid this plate.

The Rollease tubing we use has proper tines (internal extruded ridges) that lock the adapter to the tube, so a setscrew is not necessary.

If you need to use a setscrew to lock the tube to the drive adapter, here is an article that shows how to install a setscrew to lock your drive adapter to the blind tube.

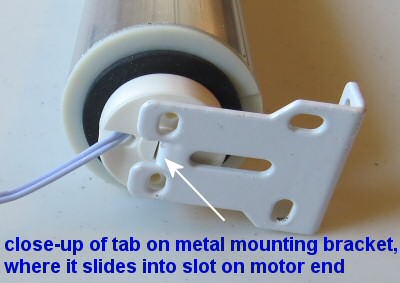

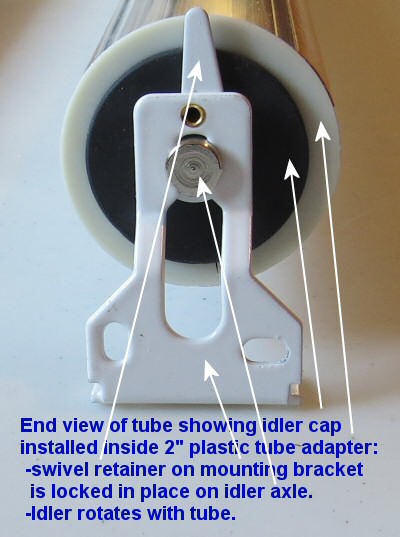

Mounting Bracket Pictures

Tube end view showing mounting bracket tab locked into motor head slot, with 2" plastic adapter for crown roller installed. Please note that we may occasionally supply different mounting brackets, but they all function in a similar fashion:

Tube end view showing end cap idler locked into mounting bracket (with 2" plastic adapter installed):

Shopping Cart Home - Start Here

Shopping Cart Home - Start Here Remote Controls for Radio Equipped Motors

Remote Controls for Radio Equipped Motors DIY Starter Kits for Window Shades

DIY Starter Kits for Window Shades DIY Starter Kits for Window Openers

DIY Starter Kits for Window Openers ZWAVE Blind & Shade Controllers

ZWAVE Blind & Shade Controllers How To Choose the Right Blind & Shade Motor

How To Choose the Right Blind & Shade Motor Select tubular Motor (Comparison table)

Select tubular Motor (Comparison table) Choose RollerTrol Battery & Solar Motors

Choose RollerTrol Battery & Solar Motors DIY Roller Blind Motors - FAQ

DIY Roller Blind Motors - FAQ How To Insert Blind Motors & Attach Brackets

How To Insert Blind Motors & Attach Brackets Calculate your Blind or Shade fabric Weight

Calculate your Blind or Shade fabric Weight Select Tube Size for Blind Motor

Select Tube Size for Blind Motor How to Insert Blind Motors Into Tube

How to Insert Blind Motors Into Tube How to Insert Blind Motors Into Tube with Adapters

How to Insert Blind Motors Into Tube with Adapters Attach Mounting Brackets - Standard + Mini Series

Attach Mounting Brackets - Standard + Mini Series Attach Mounting Brackets - MAXI Blind Series

Attach Mounting Brackets - MAXI Blind Series How To Set Up Radio Equipped Blind & Shade Motors

How To Set Up Radio Equipped Blind & Shade Motors Series P Radio Remote Control Motors

Series P Radio Remote Control Motors Series G Radio Remote Control Motors

Series G Radio Remote Control Motors Series R Radio Remote Control Motors

Series R Radio Remote Control Motors BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors How To Set Up Window/Skylight Openers

How To Set Up Window/Skylight Openers Introduction: Window & Skylight (K Series)

Introduction: Window & Skylight (K Series) BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Z-Wave Interfacing for Shade & Opener Motors

Z-Wave Interfacing for Shade & Opener Motors Wired Wall Switch Control of Window Openers

Wired Wall Switch Control of Window Openers How To Use Alexa With Our Motors & Window Openers

How To Use Alexa With Our Motors & Window Openers How To Use BroadLink Phone App Hub With Our Motors

How To Use BroadLink Phone App Hub With Our Motors How To Set Up ShadeSlider Skylight or Bottom-Up Blind

How To Set Up ShadeSlider Skylight or Bottom-Up Blind How To Retrofit RV, Boat and Motorhome Blinds

How To Retrofit RV, Boat and Motorhome Blinds How To Set Up Non-Radio Motors

How To Set Up Non-Radio Motors Operation & Travel Limits of Non-Radio Motors

Operation & Travel Limits of Non-Radio Motors Make a Simple DC Motor Reversing Switch

Make a Simple DC Motor Reversing Switch How To Set Up ZWAVE Control

How To Set Up ZWAVE Control ZWAVE Controller for G Series Radio motors

ZWAVE Controller for G Series Radio motors ZWAVE Door/Window Opening Detection

ZWAVE Door/Window Opening Detection ZWAVE Motion Detector with Temperature Sensing

ZWAVE Motion Detector with Temperature Sensing Motorized Window Blinds & Shades

Motorized Window Blinds & Shades Motorized Dual Window Shade

Motorized Dual Window Shade Make Motorized Blackout Blinds

Make Motorized Blackout Blinds Phone-Tablet-PC Control for Motorized Blinds

Phone-Tablet-PC Control for Motorized Blinds Mini Motor for Existing Shade Retrofit

Mini Motor for Existing Shade Retrofit Roman Shade Retrofit

Roman Shade Retrofit Make a Motorized Window Opener

Make a Motorized Window Opener Blind & Shade Motors for RV & Boats

Blind & Shade Motors for RV & Boats Make Your Own Projector Screen

Make Your Own Projector Screen Curtain Closer: Ultimate Home Theater

Curtain Closer: Ultimate Home Theater Wireless Battery Operated Drapery Motor Kit

Wireless Battery Operated Drapery Motor Kit Make a Motorized Bottom-Up Shade

Make a Motorized Bottom-Up Shade Make a Motorized Skylight Opener

Make a Motorized Skylight Opener BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Why Buy From US?

Why Buy From US? Background & Mission Statement

Background & Mission Statement Customer DIY Testimonials

Customer DIY Testimonials Site Map - Search All Pages

Site Map - Search All Pages Why Buy From US?

Why Buy From US? RollerTrol Users Forum

RollerTrol Users Forum Contact Page

Contact Page