Introduction: ShadeSlider™ Cellular Skylight Shade System

DIY Motorized remote control skylight blinds and shades can be easily made with our ShadeSlider™ remote control skylight and bottom-up window shade kit for residential or commercial applications. Discover how easily it can be operated with our standard 8 channel hand held remotes, our standard RF wireless wall switches, and by phone, tablet or PC with our ZWAVE add-on.

The Vera™ compatible digital radio controlled ShadeSlider™ sytem has a low power, very energy efficient 12v motor, and you can also order it with our built-in battery motors (with solar charging option).

The unit shown in the video above is about 5' x 8', with optional soft start LED strip lighting installed on each side. It is a highly scalable solution, and the entire unit runs on 12 volts DC and can be solar and/or battery powered. It also comes with a 110/220 AC power supply, if you prefer.

Ideal for use with cellular shade material, it can be adapted for many applications: skylights, bottom-up window shades, greenhouse shade systems, pergolas, sliding cupboard doors, etc.

Feature Summary: ShadeSlider™ Blind & Shade System

- Scalable design handles coverings for a wide range of sizes

- Works at any angle, including vertical or horizontal

- Compatible with our multi-channel hand held or wall mount wireless remotes

- Compatible with our Vera/ZWAVE system: operate with phone, tablet, or PC

- Battery backup with RV, marine, car, motorcycle, or Li battery

- Special low standby circuitry for low power/solar applications

- NodeSwitch™ microprocessor control option for LED companion soft-start lighting

The ShadeSlider™ is available for purchase in our online store:

skylight & cellular shade and blind motor kits

We also sell light filtering (translucent) and blackout cellular fabrics on our custom shade website.

What You'll Need to Buy Locally to Make a Skylight Shade:

- Wood to make the frame (we used 1x4)

- Wood for the leader bar (we used 1x2)

- Fastenings for the chain to the leader bar

- Torque transfer tube at one end, 1.25" ABS or EMT works well

- Tape or stapler for fastening cellular material

- Some wood screws for fastening motor and sprocket mounting brackets, etc

Applications & Usage Notes: ShadeSlider™ Blind & Shade System

You can make our ShadeSlider™ kit product work for just about any size of window or skylight shade application; that was the whole idea behind it. The length of tubing you choose for the torque transfer tube determines the width, and the chain determines the length.

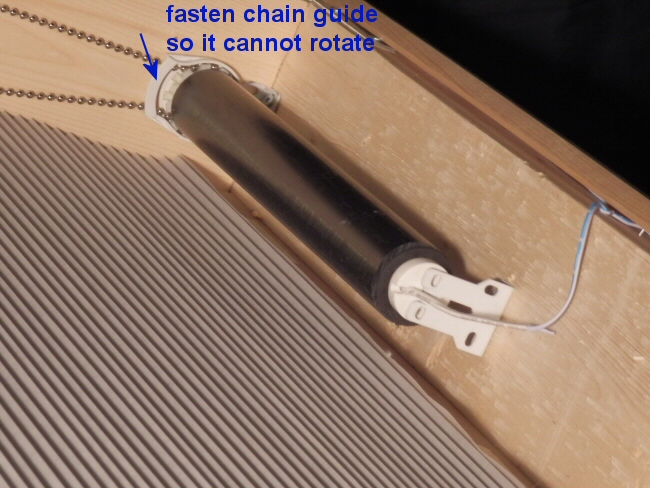

You can use 1 1/4" EMT steel conduit that works well for the tubing (and ABS or PVC). In the pictures below, we used ABS plumbing pipe, but we found that it is acoustically resonant (noisier); we think that EMT is the better choice. Although it is harder to cut and drill, it is extremely strong and quiet. Please note that we now supply the special tubing for the motor.

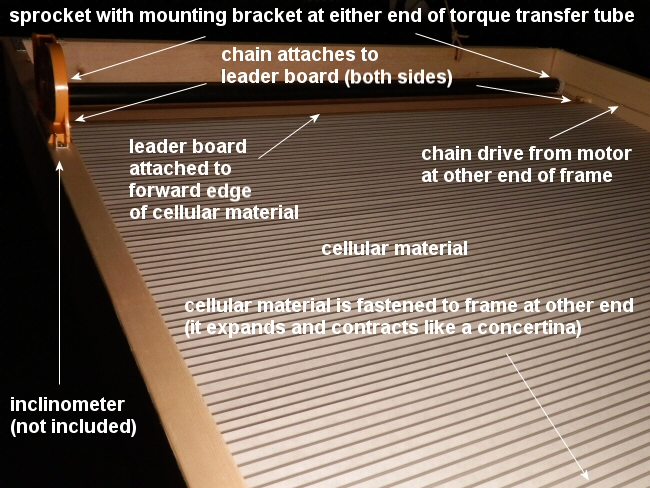

Cellular shade material comes in various forms: translucent, blackout (cells are silvered internally). You attach one end to the frame with staples and/or tape, and make a leader bar for the traveling end (we used a 1x2). The cellular fabric is stretched across the opening, forming a rigid membrane. When it retracts, it collapses in accordion-like fashion to a very small size.

For control you can use our radio motor version, which can be extended to work from your phone, PC or tablet. Or you could go to a minimalist wall switch configuration, with a non-radio motor (which also has an interface to connect with other home automation systems).

The width and height of the structure can be anything you like, within reason, until you exceed the lift capacity of the motor.

The motors run on 12v, but there is also a battery type option that is completely wireless (with solar charging option too).

Here are the kit options:

skylight & bottom-up shade motor kits

Explanations: How ShadeSlider™ Works

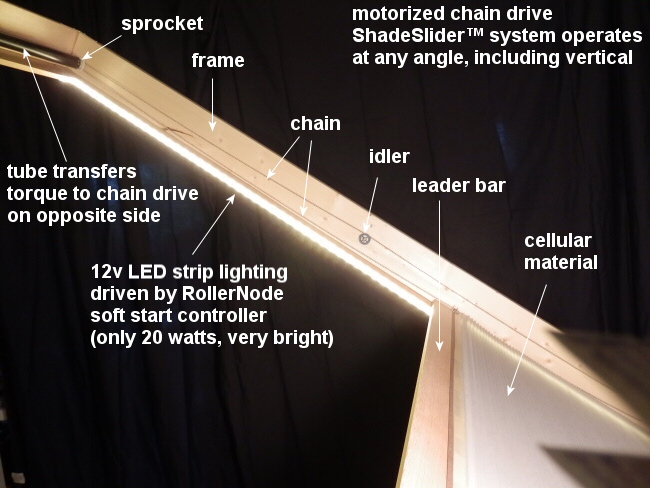

Basically, you can think of this as two 'clotheslines' with 'pulleys' on either side of the skylight, window or whatever it is you want to cover (for the purpose of this discussion, we'll refer to it as a skylight shade).

But instead of pulleys, we use sprockets, and instead of clothesline wire, we use chain. So there is zero slippage, without a requirement for any particular tension.

The main parts of the system are located at each end of the skylight, with a chain (instead of clothesline) running from one end to the other, on both sides for an even pull.

At one end, a tube that is the width of the skylight has sprockets (instead of pulleys) inserted in each end. This torque transfer tube connects the sprockets (pulleys) together so that the chains (clotheslines) on either side move in unison.

Figure 1: Torque transfer tube details (top view of demo unit in video)

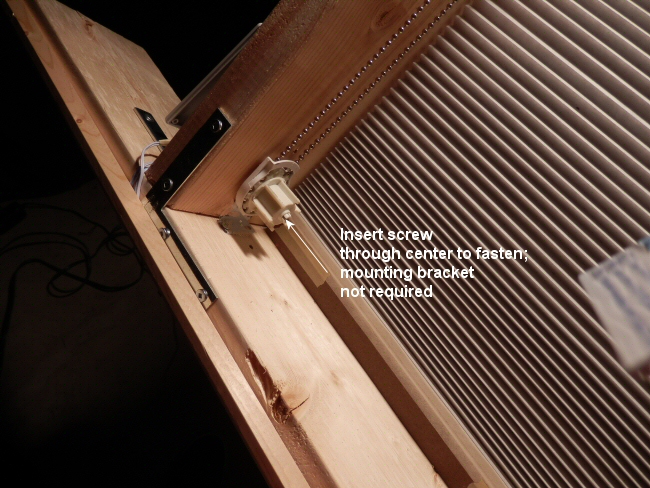

At the other end of the skylight, one side has a drive sprocket attached to a motor, which applies power to operate the entire system. The other side has an idler sprocket to complete the chain loop.

Figure 2: Remote control tubular motor with chain and sprocket, inside 1 1/4" ABS plumbing pipe

Figure 3: Idler sprocket completes the chain loop from the torque transfer tube

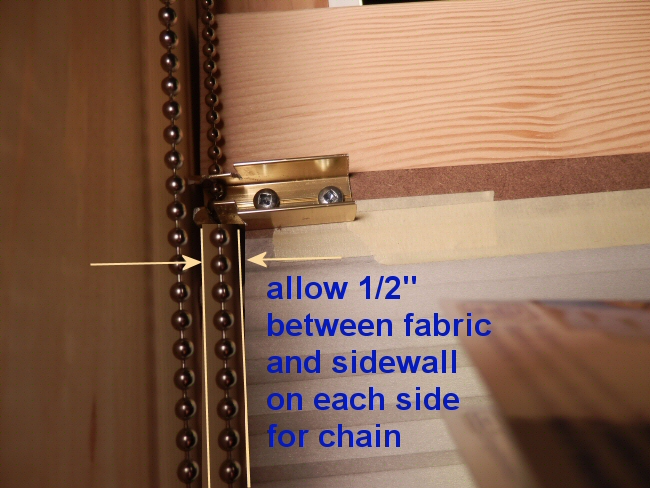

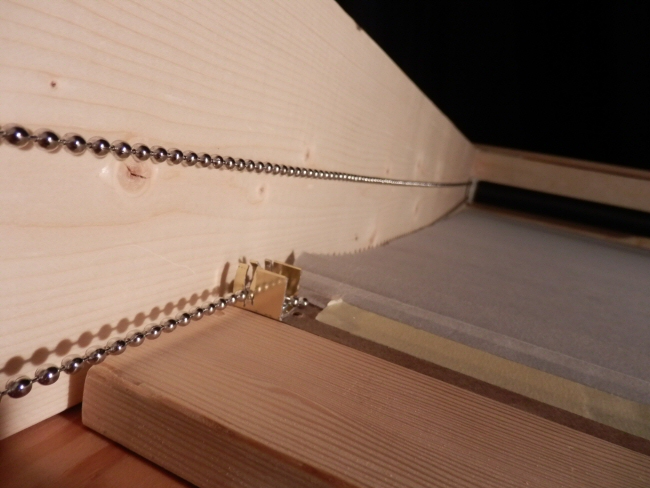

This is not an infinite loop system - the point where the chain joins is the point of attachment for the leader bar that drags the entire shade forward or backward. You can use U channel or some other type of fastening to connect to the leaderboard.

The pictures show stainless steel chain being used, but metal chain is expensive, noisy and not necessary. Now we use nylon bead chain; it is affordable, lightweight, very strong and much quieter.

Figure 4: Shade leader bar attached to chain with u-channel can be easily adjusted

Figure 5: Another view of adjustable leader bar attachment, motor in background

The LED strip lighting is completely optional; we just wanted to show how it creates a nice effect.

Figure 6: LED strip lighting provides indirect lighting effect on cellular material

We sincerely hope you enjoy using these advanced motors; if you have any questions, please feel free to contact us at any time!

Shopping Cart Home - Start Here

Shopping Cart Home - Start Here Remote Controls for Radio Equipped Motors

Remote Controls for Radio Equipped Motors DIY Starter Kits for Window Shades

DIY Starter Kits for Window Shades DIY Starter Kits for Window Openers

DIY Starter Kits for Window Openers ZWAVE Blind & Shade Controllers

ZWAVE Blind & Shade Controllers How To Choose the Right Blind & Shade Motor

How To Choose the Right Blind & Shade Motor Select tubular Motor (Comparison table)

Select tubular Motor (Comparison table) Choose RollerTrol Battery & Solar Motors

Choose RollerTrol Battery & Solar Motors DIY Roller Blind Motors - FAQ

DIY Roller Blind Motors - FAQ How To Insert Blind Motors & Attach Brackets

How To Insert Blind Motors & Attach Brackets Calculate your Blind or Shade fabric Weight

Calculate your Blind or Shade fabric Weight Select Tube Size for Blind Motor

Select Tube Size for Blind Motor How to Insert Blind Motors Into Tube

How to Insert Blind Motors Into Tube How to Insert Blind Motors Into Tube with Adapters

How to Insert Blind Motors Into Tube with Adapters Attach Mounting Brackets - Standard + Mini Series

Attach Mounting Brackets - Standard + Mini Series Attach Mounting Brackets - MAXI Blind Series

Attach Mounting Brackets - MAXI Blind Series How To Set Up Radio Equipped Blind & Shade Motors

How To Set Up Radio Equipped Blind & Shade Motors Series P Radio Remote Control Motors

Series P Radio Remote Control Motors Series G Radio Remote Control Motors

Series G Radio Remote Control Motors Series R Radio Remote Control Motors

Series R Radio Remote Control Motors BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors How To Set Up Window/Skylight Openers

How To Set Up Window/Skylight Openers Introduction: Window & Skylight (K Series)

Introduction: Window & Skylight (K Series) BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Z-Wave Interfacing for Shade & Opener Motors

Z-Wave Interfacing for Shade & Opener Motors Wired Wall Switch Control of Window Openers

Wired Wall Switch Control of Window Openers How To Use Alexa With Our Motors & Window Openers

How To Use Alexa With Our Motors & Window Openers How To Use BroadLink Phone App Hub With Our Motors

How To Use BroadLink Phone App Hub With Our Motors How To Set Up ShadeSlider Skylight or Bottom-Up Blind

How To Set Up ShadeSlider Skylight or Bottom-Up Blind How To Retrofit RV, Boat and Motorhome Blinds

How To Retrofit RV, Boat and Motorhome Blinds How To Set Up Non-Radio Motors

How To Set Up Non-Radio Motors Operation & Travel Limits of Non-Radio Motors

Operation & Travel Limits of Non-Radio Motors Make a Simple DC Motor Reversing Switch

Make a Simple DC Motor Reversing Switch How To Set Up ZWAVE Control

How To Set Up ZWAVE Control ZWAVE Controller for G Series Radio motors

ZWAVE Controller for G Series Radio motors ZWAVE Door/Window Opening Detection

ZWAVE Door/Window Opening Detection ZWAVE Motion Detector with Temperature Sensing

ZWAVE Motion Detector with Temperature Sensing Motorized Window Blinds & Shades

Motorized Window Blinds & Shades Motorized Dual Window Shade

Motorized Dual Window Shade Make Motorized Blackout Blinds

Make Motorized Blackout Blinds Phone-Tablet-PC Control for Motorized Blinds

Phone-Tablet-PC Control for Motorized Blinds Mini Motor for Existing Shade Retrofit

Mini Motor for Existing Shade Retrofit Roman Shade Retrofit

Roman Shade Retrofit Make a Motorized Window Opener

Make a Motorized Window Opener Blind & Shade Motors for RV & Boats

Blind & Shade Motors for RV & Boats Make Your Own Projector Screen

Make Your Own Projector Screen Curtain Closer: Ultimate Home Theater

Curtain Closer: Ultimate Home Theater Wireless Battery Operated Drapery Motor Kit

Wireless Battery Operated Drapery Motor Kit Make a Motorized Bottom-Up Shade

Make a Motorized Bottom-Up Shade Make a Motorized Skylight Opener

Make a Motorized Skylight Opener BroadLink RF/IR Hub System for Motors

BroadLink RF/IR Hub System for Motors Why Buy From US?

Why Buy From US? Background & Mission Statement

Background & Mission Statement Customer DIY Testimonials

Customer DIY Testimonials Site Map - Search All Pages

Site Map - Search All Pages Why Buy From US?

Why Buy From US? RollerTrol Users Forum

RollerTrol Users Forum Contact Page

Contact Page